Vibratory Sieves, Screens and Separators

Industrial vibratory sieves, screeners and separators are all machines dedicated to improve quality using vibration and product material particle sizes. Gough Engineering have always maintained a bespoke design solution portfolio, where each application is a little different that the other. And, every detail can make a difference in product flow between processes, the right screening solution for the subsequent downstream production line.

Gough Engineering has earned a trusted reputation for delivering high efficiency, innovative solutions in precision screening and material separation across various industries.

Gough Screening Systems

Circular Single Deck Sieving & Screening

These machines use a single mesh for two fraction separation, usually classed as oversize (unwanted material and debris) with good product going through the mesh.

Circular Multi-Deck Separation

With additional deck options you can separate your product material into 2, 3 or 4 fractions. Each fraction classed as oversize, middle fractions and fines all ready for further processing and automation.

Linear Vibrating Screening

Alternatively, we can supply larger screening options in a linear form, utilising larger screen areas and vibration areas to achieve your correct screening requirements with options for single screen and twin screen designs.

Don't worry, we have your integration covered

Types of vibratory sieves and separators

We offer a wide range of vibrating sieves, screens, and separators, each configured to meet specific application requirements regardless of throughput requirements. Our vibratory equipment is designed to deliver reliable results, whether you require batch sieving, liquid and powder separation, or pharmaceutical-grade material screening.

-

Batch Sieves (GBS)

Our compact vibratory system is ideal for efficiently sieving liquids and powders. It's a versatile solution for industries that require high-quality, consistent results in small to medium-sized batches.

-

Vibraflo (GVF) Circular Screen

If you require high-volume circular screening, our Vibraflo vibratory screens are up to the task. They are designed to handle large volumes of materials efficiently.

-

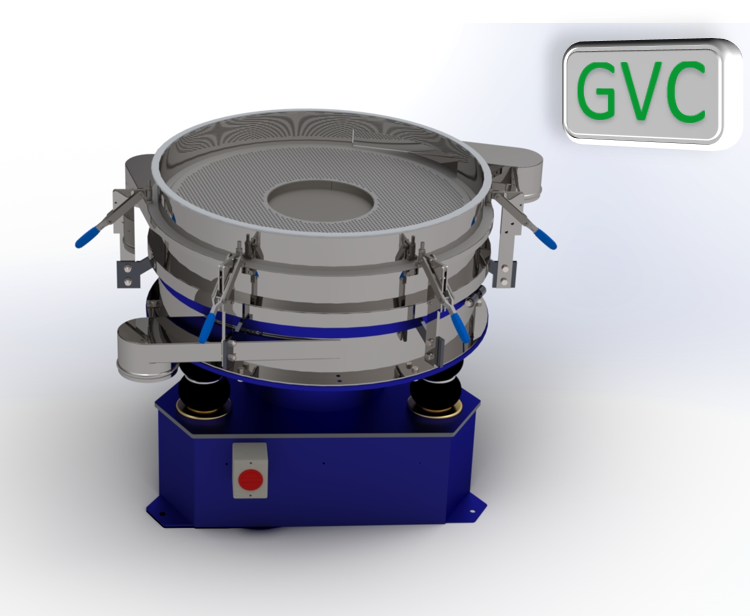

Vibrecon (GVC) Circular Separator

For multi-deck circular separation needs, our vibratory screen separators offer exceptional performance. They're designed to handle a wide range of raw materials, making them suitable for diverse industrial applications.

-

Pellet Screener (GVC)

In plastic pellet screening applications, our pellet screens provide efficient and reliable screening results, ensuring product quality and consistency.

-

Linear Vibrating Screen (GLVS)

When you need a linear product screening machine, our equipment delivers. Linear vibrating screens are perfect for applications where the screening process needs to occur in a linear manner.

-

Pharmaceutical Sifter

When dealing with pharmaceutical-grade materials, precision and hygiene are paramount. Our pharmaceutical sifters meet these stringent requirements while delivering optimal separation results.

-

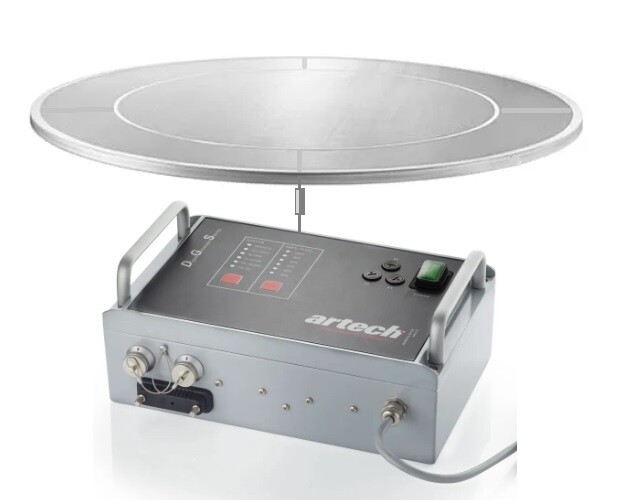

Ultrasonic Screening

For industries that demand ultrasonic screening de-blinding equipment, our solutions ensure thorough cleaning and separation, maintaining product integrity.

Trial Options for Applications Testing

We understand that every industrial process is unique. That's why we offer a range machines to trial in our testing facility.

Our team of skilled engineers can help you choose the right accessories and equipment to optimise your vibratory sieve or separator for your specific application.

Hire Options for Proof Testing

Gough Engineering has stock machines ready for hiring at your premises to check suitability. Alternatively, we can trial your material on our machines to see what really works best for your screening requirements.

Reality Cases

Peruse our reality case examples to discover how customers use our equipment.