Industrial batch sieving machines

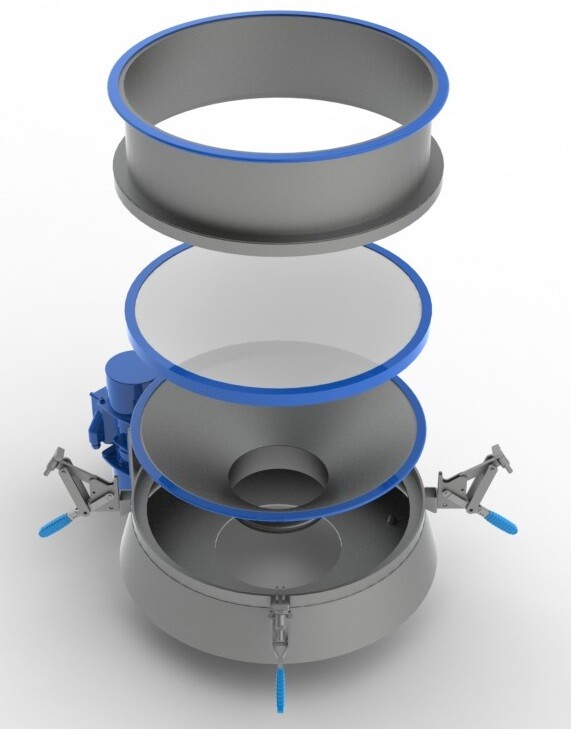

Sieves, screeners, or check screens are used to improve your good product material quality removing larger contaminants or debris. The industrial, vibratory Gough Batch Sieve (GBS) is a superb industrial sieving process for any industry. It will sift and sieve material, guaranteeing better product quality for your next process. It has a heavy-duty design for long term operations, ergonomic design for ease-of-use with many options for effective processing.

Introduction

Simple & Effective Sieving

Maximising your product quality reducing waste...

The Batch Sieve is very compact, especially in height and can have a mesh screen diameter of 550mm or 850mm depending on your operations.

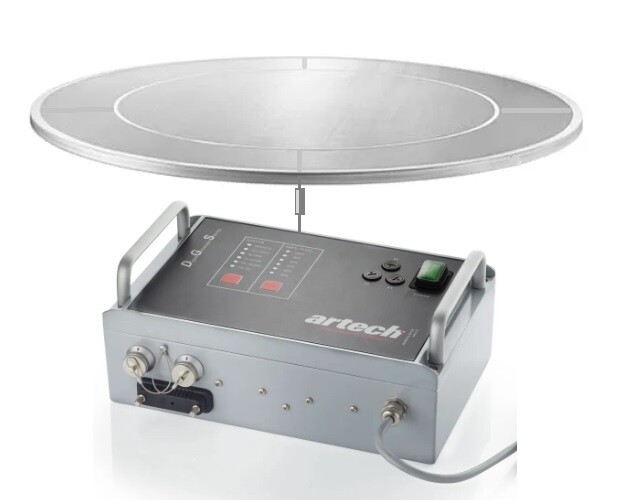

It uses a modern efficient sealed motor, producing smooth vibration to improve product material quality for further processing

ITS MISSION: To removing lumps and filter out unwanted materials such as conglomerated, large contaminants and bag debris based on particle size including as well as airing product material as used in the bakeries.

This unit depicts a GBS550 sieve, with tipping hood, resting bars for a Rip&Tip debagging, operator steps for large receiving containers, enclosed cabinet with extraction ports (click below).

Also see our de-dusting feature here to minimise dust in your environment, click below.

Key advantages of our sieving machine

Robust design

The durable and robust design can handle a wide range of industrial processing applications.

Efficient processing

The single vibratory motor encourages steady product flow and sieving, reducing the time needed for processing.

Easy maintenance

The simple design requires little maintenance and will continue to operate with minimal intervention.

Super ergonomics

The Gough Batch Sieve (GBS) is designed and tailored to your operations, keeping health & Safety a priority.

Batch Sieve Models

Model |

Screen Diameter (mm) | Screen Area (m2) | No of meshes | Mesh apertures sizes |

GBS 550 |

550 | 0.26 | 1 | 30microns to 12mm |

GBS 850 |

850 | 0.56 | 1 | 30microns to 12mm |

Special Gough Rip & Tip Stations

Read more by clicking on the link on how Gough Engineering's popular Rip & Tip Stations are a superb way for operators to simplify any de-bagging & handling requirements

Batch Sieve Options

- Batch sieve mounted on your operations workspace.

- Batch sieve with a Gough support stand.

- Batch sieve and stand with fixed or pivoting hood.

- Mobile support stand with castors or with steps built into frame for larger receiving containers.

- Flexible connectors to minimise dust.

- Selection of stainless-steel mesh available, drop in or integrated to deck with perforated plate options.

- Ultrasonic options for fine mesh sizes and deblinding.

- Extraction units with built in filter/ extraction system.

- Removable underslung draw magnet to remove ferrous material.

- Extra containment panels on support frame underneath the sieve, and more

Enhancements...

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Floveyor and Sieve for Flour in Corn Production

Safe handling and improving quality of product material by sieving was paramount for a UK company...

Contact us today

Want to find our more on our superb batch sieve solution and all its benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Flipbook for Sieves

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

Some answers from GOBi (Gough Objective BOT intelligence)

Can a sieve be used without a support stand?

Can a sieve have more than one screen?

No, a sieve only has one screen for just 2 fraction separation - same as a Gough Vibraflo (GVF) machine. However, if you need 2 or 3 screens inside one machine then we can supply the Gough Vibrecon (GVC) machine for this type of multi-layer separations.

What type of mesh aperture sizes do you supply?

What is the best method to deliver to a sieve?

It depends on your delivery process. If you are manually de-bagging say a 25kg bag then a Rip & Tip station with a bag rest area would work well. If you want to empty multiple bags into a hopper, then a vibratory feeder can be useful for this delivery method. Gough supply these units as well.

.jpg?noresize&width=225&height=180&name=Gough%20Engineering%20Batch%20Sieve%20with%20Top%20Cover%20P6%20Tayto%20(14).jpg)