Industry: Recycling

With more efforts into recycling all types of materials these days Gough Engineering has supplied material handling transfer and separation equipment for companies specialising in this fairly new industry. Companies who work with both local government and environment agencies to help increase the effectiveness of their recycling streams can rely on Gough Engineering to supply the right transfer and separation processes equipment. In some cases for example, the linear vibratory screen is a suitable solution in waste recycling for the food, glass, shredded or crushed materials from different industries.

Quality

Quality can mean many things, but here its all about quality of raw materials or additional ingredients to manufacture to the standards you need. If its masterbatch, Gough Engineering can help...

Productivity

By automating a process, the flow of ingredients within your production will increase. Product will transfer from one process to another, occasionally automatically filtering out unwanted material to achieve final product quality levels with satisfaction.

Reliability

Superb build quality will provide a machine that will endure many years of operations. It's like Triggers broom, by changing the parts when needed, it goes on and on and on...

WEE

Recycling of WEEE (Waste Electrical and Electronic Equipment) is a specialist part of the waste and recycling industry. Over the past 10 years it has been a rapidly growing industry due to the implementation at government level of the original WEEE Directive in the UK (2006). This led to specific requirements in the recovery, reuse, recycling and treatment of WEEE components.

Further information on the WEEE regulations 2013 can be found in the Government Guidance Notes produced by the Department for INNOVATION and SKILLS.

WEEE includes predominately products that have a plug or a battery requirement and 2 million tonnes (estimated) are discarded by companies and household items per year in the UK alone which can include:

- Large household appliances

- Small household appliances

- IT and telecommunication equipment

- Consumer equipment

- Lighting equipment

- Electrical & electronic tools

- Toys, leisure and sports equipment

- Medical devices

- Monitoring and control equipment

- Automatic dispensers

PET Bottle Recycling

Once the collected post-consumer PET (polyethylene terephthalate) bottles are delivered to the Materials Recovery Facilities (MRF) it is sorted and separated from other materials. Further processing by colour is made for specific application demand and pricing and when required crushing, washing, separating and drying can be used for final product sale.

Gough Engineering can provide the right equipment for your separation processes and elevators for product transfer to suit your production design.

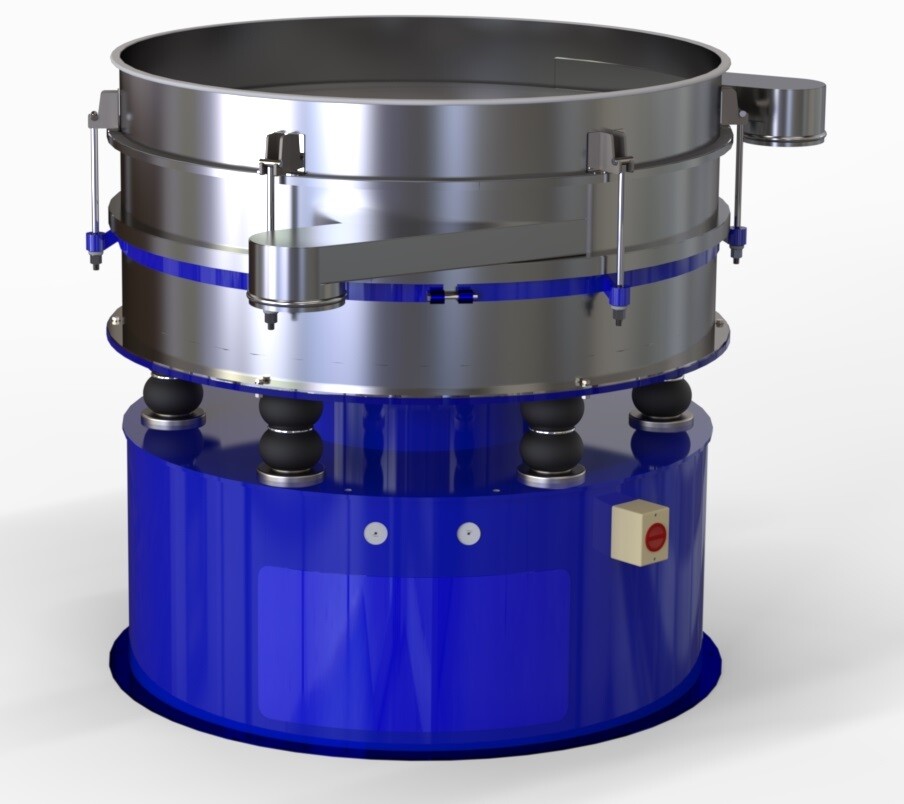

Circular vibratory screening or linear vibratory screening or feeding can be specifically designed by Gough Engineering to allow your PET product to be classified correctly.

Rubber Recycling

Over the past few years the demand for recycling many popular materials such as plastics and paper but rubber has also seen a dramatic increased in demand as new applications are developed.

Tyre rubber in the past was the most common source of rubber headed for the waste sites. However, new developments in the use of granulated and refined rubber into more manageable sizes and crumbs allow for new applications such as astroturf, playground surfaces, matting, flooring and many more.

Gough Engineering has helped companies provide screening and separating processes using linear vibratory screens.

Product Range Examples

We supply solutions to a range of industries, including food, plastics, recycling, pharmaceuticals, and chemicals. Our equipment is designed to meet the unique demands of each sector, ensuring efficiency, quality, and reliability in every application.

Gough Engineering

Experts in recycle processing equipment for sieving, separating and transferring your product safely and effectively.

Saving the planet along the way.

Call our team of highly skilled engineers to discuss your requirements on 01782 567770 or online.

.jpg?noresize&width=675&height=540&name=Gough%20Linear%20Screen%20GLVS%20(Declined).jpg)