Equipment checklist

Gough & Co Engineering manufacture high quality machinery solutions for a wide range of industries including foods, snacks, confectionary, plastics, chemicals, pharmaceuticals and recycling recovery. We pride ourselves on excellent parts and service advice and help the customers on many levels. One aspect discussed with customer is the checks we would recommend in looking after your Gough equipment. The following lists will help identify any areas of concern and our Parts & Service department is here to advise on the best course of action.

Why do this?

Keeping your machines working in tip top condition will require a check on not only its performance, but condition.

By performing this function, the machine will perform for many years, or decades as it should.

Purpose

The checklists are defined to help in focusing in those components that may require attention. Noticing potential problems and scheduling parts replacement will avoid unexpected downtimes.

Stock

Gough does stock major components in its own facility for quick turnaround and delivery. Some parts do require some working hours and can be scheduled for delivery to suit your planned maintenance,

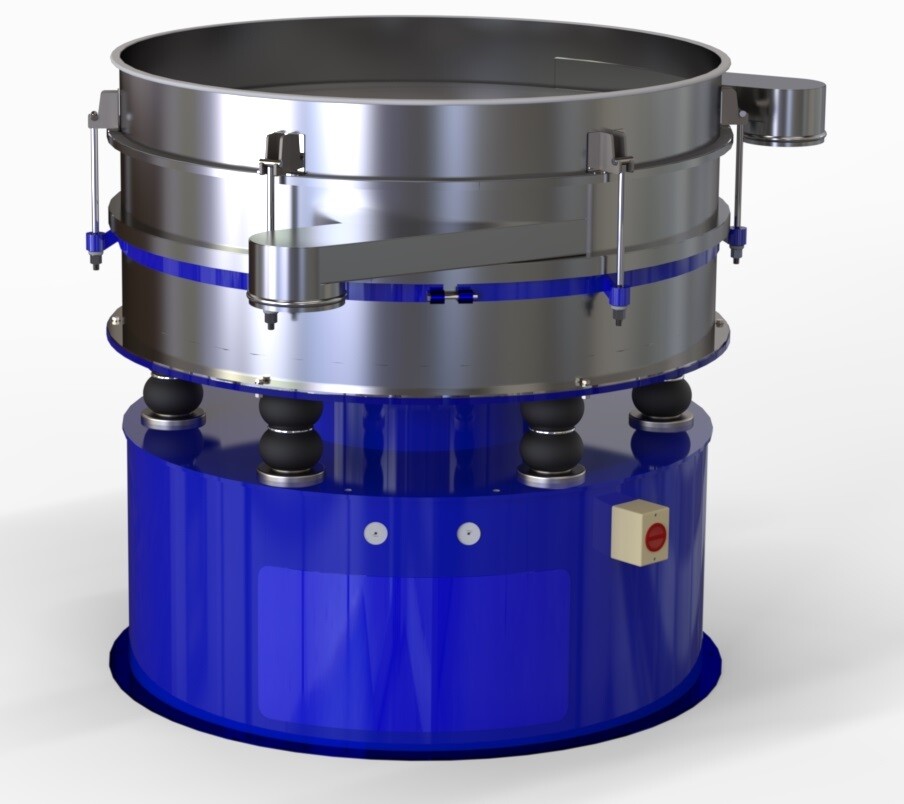

Sieve CheckList

- Check motor condition/safe wiring.

- Check toggle clamp tension.

- Check mesh / perforated plate condition (damage/dents/profile).

- Check cracks on deck rim and spouts.

- Check antivibration rubber mounts / wheel locking mechanism.

- Check condition of frame seals.

Gough Vibrecon® CheckList

- Check air pressure on air bellows (6.5 bar correct working pressure).

- Check Supply Voltage is correct and isolator is working.

- Check toggle clamp tension.

- Check mesh / perforated plate condition (damage/dents/profile).

- Check cracks on deck rim and spouts.

- Vibraflo – check springs for damage.

- Vibrecon check air bellows for rubber perishing.

- Check chassis mountings / wheel locking mechanism.

- Check condition of frame seal.

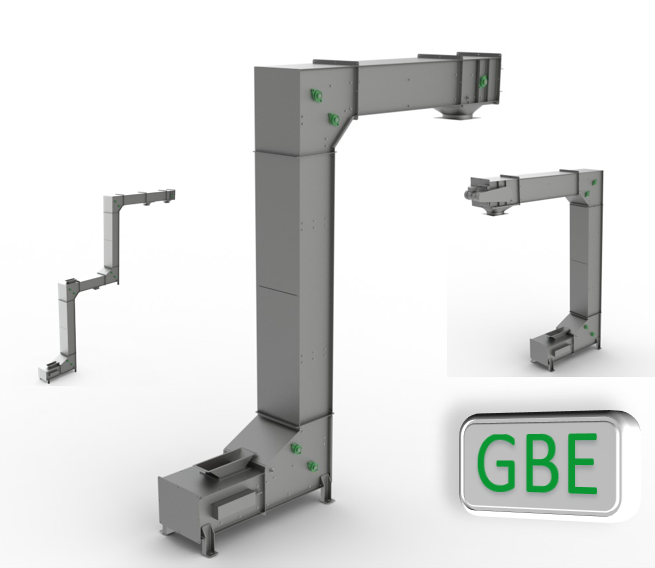

Gough Elevator CheckList

- Torque limiter settings – test for presence of oil, grease, moisture, corrosion on friction pads.

- Check transmission chain tension.

- Check bucket condition for broken corners & lips/missing buckets.

- Lubrication levels check if required.

- Drive chain greasing, shaft bearings.

- Elevator main chains- check slack take-up & adjusted correctly if necessary.

Daily Checks

- Material Flow and throughput.

- Discharge ramps are operating on call and / or that the fixed ramp is aligned.

- Power transmission drive chain alignment.

- Torque limiter is not slipping. NOTE: That the clutch may need adjustment after the initial 20 to 40 hours of running as the machine parts bed in.

Weekly Checks

- Feeder flow and throughput.

- All tipping ramps are operating smoothly and linkages are secure.

- All buckets are secure.

- Inspect the elevator casing for material build-up etc. Clean out where necessary.

- Visual bucket condition check.

- Slack chain take-up adjustment is set correctly.