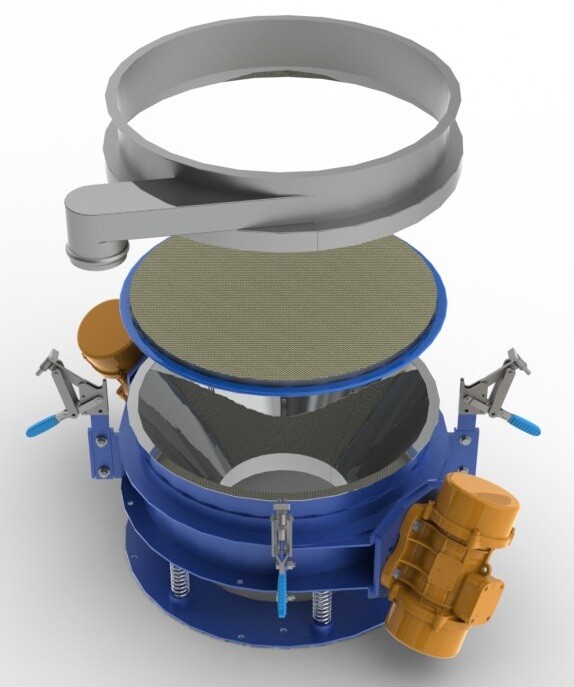

Vibraflo® Vibratory Screeners

The Gough Vibraflo Vibratory Screener (GVF) is an industrial grade, mechanical vibratory system ideal for high volume check and safety screening applications. A heavy duty design for rotary sieve applications for small, medium and high volumes.

Introduction

Super Sized

Using the Vibraflo® Vibratory Screen, you can be sure that your good product will be checked with automatic removal of lumps, oversize, and contaminants in both wet as well as dry applications.

There is an option to choose between a single screening deck configuration of the system as well as a variety of sizes to meet different throughput requirements. The sizes range from 450mm up to 1,600mm in diameter.

It is possible to process anywhere from a few grams per hour to as much as 60 tonnes per hour (depending on the product and mesh size of the system).

How it works...

Feeding

Without a lid, pour the contents into the centre of the screen and let the machine do the rest. Oversize will automatically exit, finer product discharging through the central spout underneath.

The Process

Through vibration from the powerful twin put-of-balance motors, the single screen will separate oversize (remaining on-top of the mesh) from finer good product material flowing through the central discharge spigot underneath.

Collection or Conveying

The good product can be collected underneath using your containers or bags, or product can be taken off using a transfer conveyor or feeder system.

Quick Mesh Changeovers

With releasing the quick release toggle clamps, mesh changeovers with news or or clean ones can be down in seconds.

Key advantages of our screeners

Screen areas

Industrial options for screen areas range from 0.26m2 to 1.33m2 to achieve the throughput you require.

Powerful

Large twin out-of-balance sealed motors generate the vibration you need for those continuous operations.

Easy maintenance

The simple design requires little maintenance and will continue to operate with minimal intervention.

Options

Our fabrication department can design the right support frame, with a top over and a vibratory feeder to deliver the product, if required.

Vibraflo® Model Range

Model |

Screen Diameter (mm) | Screen Area (m2) | No of Meshes | WM or PP Apertures sizes (mm) |

GVF 2 |

610 (24”) | 0.26 | 1 | WM 0.3-12 PP 3-40 |

GVF 3 |

864 (34”) | 0.53 | 1 | WM 0.3-12 PP 3-40 |

GVF 4 |

1,118 (44”) | 0.88 | 1 | WM 0.3-12 PP 3-40 |

GVF 5 |

1,372 (54”) | 1.33 | 1 | WM 0.3-12 PP 3-40 |

WM-Wire Meshes

PP - Perforated Plate

Enhancement Options

- Small Vibraflo's can be mounted on your operations workspace.

- Vibraflo with a full support stand.

- With removable top cover for dust-suppression.

- Viewing ports in top cover.

- Flexible connectors to minimise dust.

- Selection of stainless-steel mesh available, drop in or integrated to deck with perforated plate options.

- Extraction units with built in filter/ extraction system.

- Removable underslung draw magnet to remove ferrous material.

- Mobility through castor designs.

- Full dust encapsulation methods with BFM or flexi-pipe fittings.

Enhancements...

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Improving supply chain efficiency with bulk material handling

How Gough helped a bulk handling company check screen their material handling delivery system at 15,000kg/hr.

Flipbook for sieves

Flipbook for Transfer Systems

Contact us today

Want to find out more on our superb Vibraflo solution and all its benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Reach out to us

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

How many screens can I use on this machine type?

As with the batch sieve, only one screen is ever use in the machine at any time. However, you can replace the screen quickly if you wanted to perform screening using a different screen aperture.

Is the support stand optional?

Yes, the support stand is optional but can be engineered to suit your application and to raise the machine accordingly to work in conjunction with other process up and downstream.

Can I have a top cover?

Why a Vibraflo?

Using two industrial out-of-balance motors, the Vibraflo machine can give extra bounce to the product material being screened. This can help in the breaking up of larger particle sizes to check screen them through a single screen arrangement. This can also help in the throughput of the machine's capacity.

.jpg?noresize&width=1632&height=1224&name=P2%20Unilever%20Bolivia%20Ball%20Tray%20(5).jpg)