Ultrasonics

At Gough Engineering we engineer cutting-edge material handling systems. With our world-class technology, you can eliminate screen blinding and mesh blocking, significantly enhancing product throughput rates when screening with fine meshes.

Introduction

Simple & Effective Sieving

What is ultrasonics?

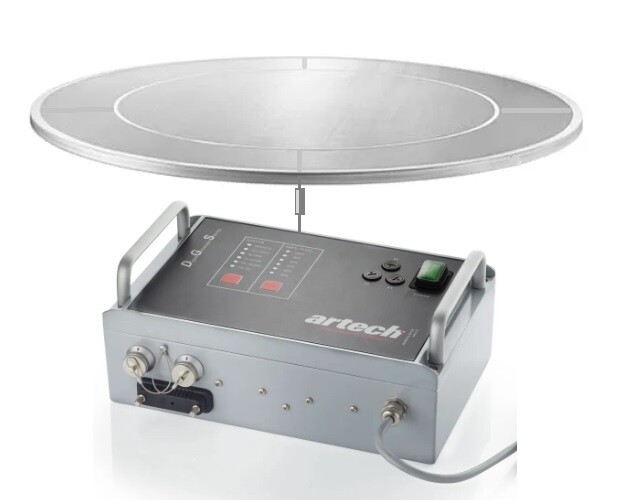

An ultrasonic screening system has three main components: a generator, a converter and a matched screen resonator with a frame.

The generator and converter work together to create high-frequency vibrations. They direct these vibrations into the resonator, which attaches to the screen frame.

These vibrations, manifested as high-frequency ultrasound waves, effectively prevent clogging, optimise material throughput and reduce process time.

Primarily used for classification, protective screening, dedusting, and conventional analysis screening in laboratories, this type of material handling equipment offers efficiency and accuracy.

Suitable for particles sized between 50 and 200 microns, our ultrasonic screening solutions excel in various industries.

Key advantages

De-blinding

They are crucial for solving screen blinding issues, particularly when dealing with fine powders. By using high-frequency vibrations, ultrasonic technology effectively prevents particles from adhering to the screen mesh, ensuring continuous and accurate screening operations.

Precision

In quality control processes, precision in particle sizing is essential. Ultrasonic screening not only stops blinding but also accurately sorts particle sizes, especially those in the fine powder category. This level of accuracy is essential for ensuring consistency in product quality and meeting stringent industry standards.

Assurance

Quality control becomes more than just a process— it becomes a guarantee. By reliably de-blinding screens, ultrasonic technology ensures consistent operation. By accurately classifying particle sizes, it enhances quality assurance, providing confidence in the integrity and purity of the final product.

Advantages...

So high throughputs, reduced cleaning and downtime and extending mesh life - all important aspects of mesh operations to keep the separation process working optimally.

Explore

our specialist solutions

We specialise in delivering superior material handling and process equipment solutions tailored to your unique requirements. Our ultrasonic screening solutions are designed to optimise your material handling processes, whether you operate in pharmaceuticals, food processing, or any other sector.

Stay ahead of the curve with the latest industry news, events, and innovations from Gough Engineering. Read our latest case studies and news articles to learn about our material handling technology.

Contact us today

Want to find our more on our superb batch sieve solution and all its benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

Can ultrasonics be used on circular and linear screens?

Can ultrasonics be used on both screens in a separator

Yes, if you have two fine mesh screens in one separator / classifier, a single ultrasonics generator can be used to power both ultrasonic screens.