Sieve Remeshing

Over time, screen mesh tension may reduce. It is important to observe correct and adequate tension in order to maintain effective screening performance. Gough & Co Engineering Ltd offers a complete and comprehensive sieve / screen re-meshing service to all its customers worldwide.

Ripped or Torn Mesh?

Do you have ripped or torn meshes? This will significantly impact on your sieving or separation process making problems later down the line in production.

Broken Frame Bonding?

Meshes can tear away from the frame bonding. If so, again this will let unwanted product through the sieving operation creating contamination or unwanted material in your good product material.

Need a Fast Response?

Gough Engineering will assess your requirements and provide a price and lead time to get you back operational and running optimally with a new mesh.

Introduction

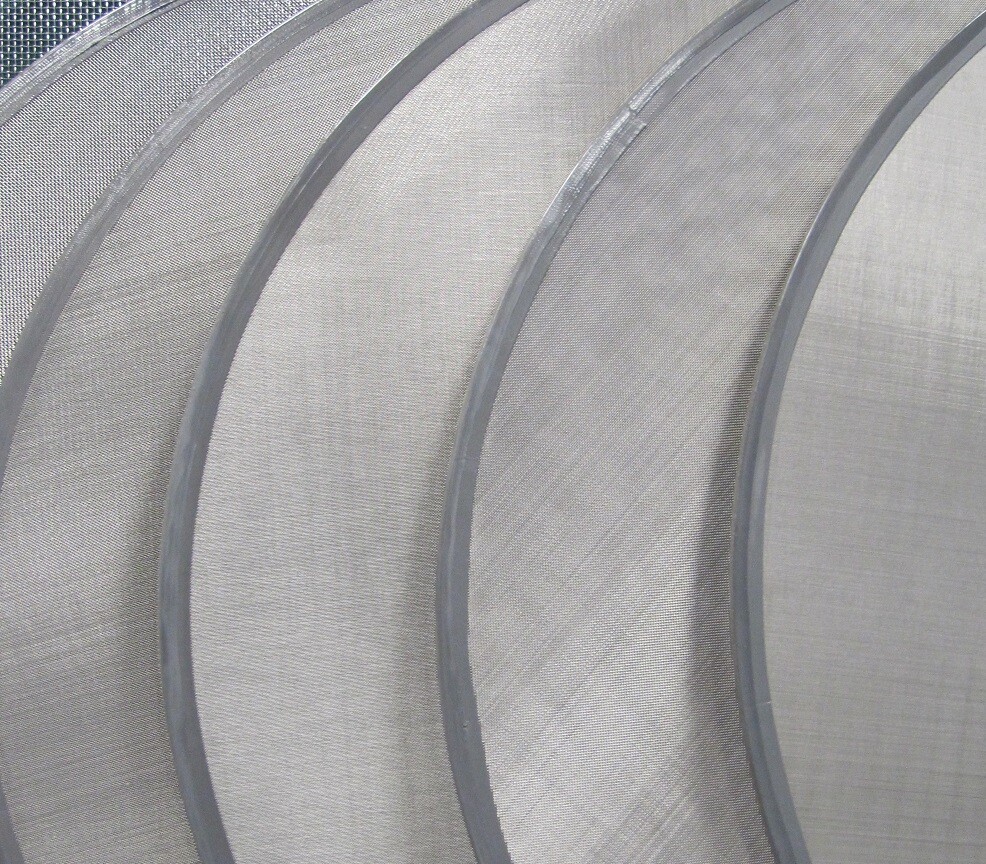

Reusable sieve frames are supplied as standard throughout our range of Vibrecon, Vibraflo and Bakery Sieve equipment.

By holding a stock of our completely interchangeable mesh frames, we can provide your production department with the option to quickly change over from one product to another, ultimately offering the ability to adjust your screening quality and efficiency. Alternatively, Gough can fit new mesh to your existing frames, with a turnaround often within just forty-eight hours!

Not only do we offer a full re-mesh service for our own range of circular frames, we also re-mesh many other different manufacturers types of rectangular and circular sieve frames.

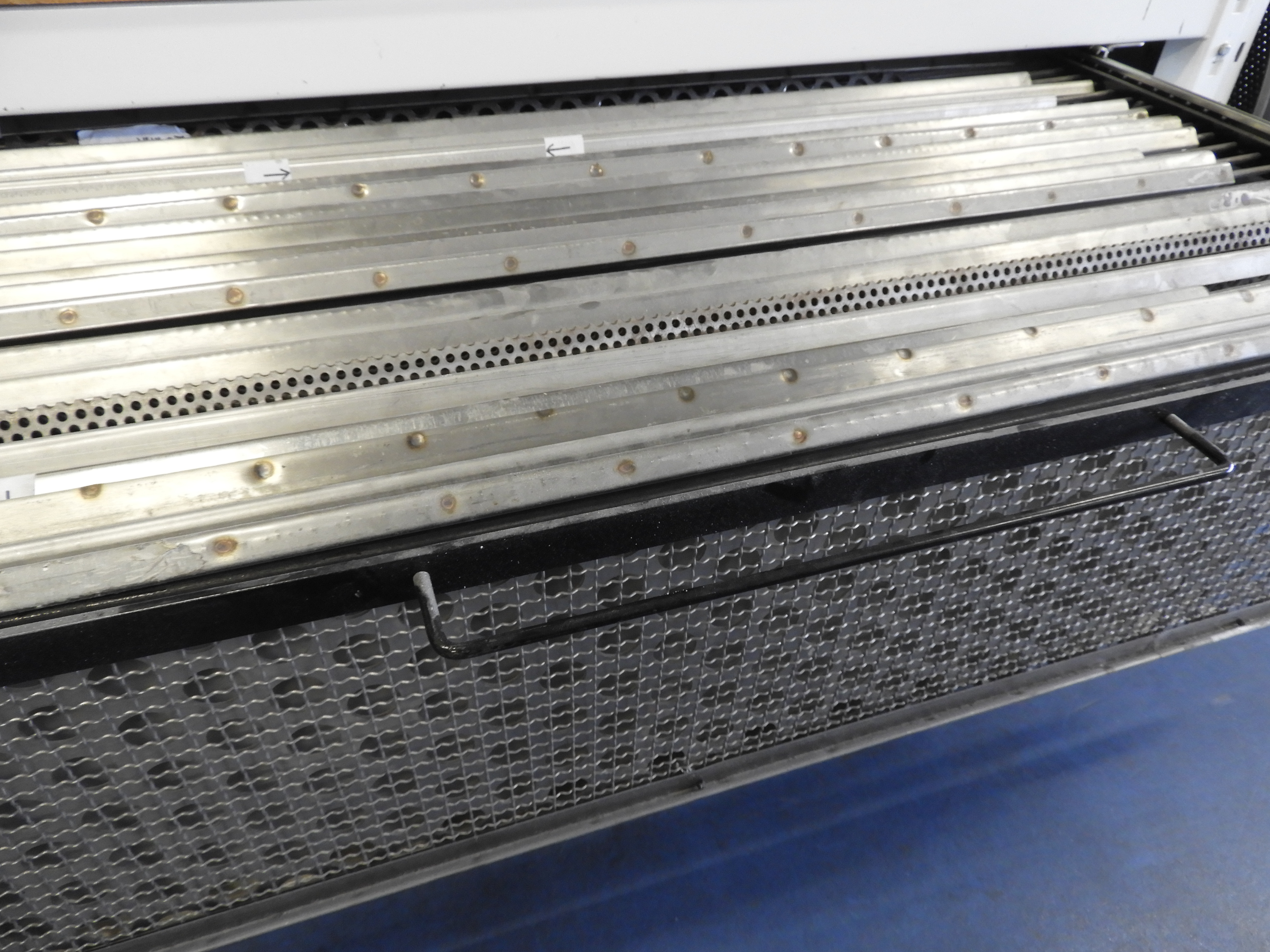

We also complete linear screen remeshing

Gough manufactures to order a large range of bespoke hook-screen mesh and perforated plates to suit your requirements. If you need a replacement hook-screen or you are looking at changing your product / process, talk to Gough – we have a solution for you!

Comprehensive Service

Frame Shapes: Circular, rectangular, square or irregular

Frame type: Standard single frame or ultrasonics frames

Frame sizes: Up to 1,300mm

Aperture Sizes

Fine Meshes Aperture = 25 microns to 1000 microns

Normal Meshes Aperture = 1 – 12 mm apertures or specials

Frames: Bonded frames or conventional clamp type

Standards: FDA (Foods) Bonded and Non-FDA (Industrial) Bonded

Quick turnaround time (subject to availability)

+44 (0)1782 567793

+44 (0)1782 567793