After Sales Support & Aftercare

At Gough Engineering, our commitment to customer satisfaction extends well beyond the initial purchase of your machinery. We understand the importance of maintenance engineering to ensure your production lines stay operational around the clock.

Our comprehensive after-sales support ensures that your equipment remains reliable and efficient over the long term, reducing the risk of breakdowns and costly downtime.

Gough Engineering's team of highly skilled engineers delivers machine maintenance services with a level of expertise that sets us apart. Often, the engineer that installed your machine will be the one carrying out its maintenance, offering an unmatched understanding of its specific needs. This continuity allows us to provide tailored equipment maintenance solutions that not only fix issues but also prevent them from occurring in the first place.

Comprehensive after-sales services

Our after-sales support goes beyond simple repairs, it’s about maintaining the optimal performance of your machinery through proactive services.

Preventative maintenance

Prevention is better than cure, especially when it comes to your production line. Rather than waiting for an issue to appear, we offer customer care health visits on a no-fee basis for existing customers.

These proactive checks are designed to identify any early warning signs and address them before they turn into major issues that could disrupt your operations. This could include lubrication of the machinery, assessing any wear, looking at performance and machine running time, spillage and noise.

Emergency repairs

Despite the best preventative measures, unexpected issues can still occur. When they do, we offer fast, reliable support to get your equipment back in operation quickly. Whether it’s a minor malfunction or a critical breakdown, our engineers will be on-site in the UK promptly to resolve the issue.

We understand that delays in machine maintenance can lead to significant production losses. That’s why we keep a large stock of essential spare parts, allowing us to replace components quickly.

For example, if a bucket in an elevator system breaks, it can cause significant production stoppages. Our team ensures that parts like these are replaced very quickly.

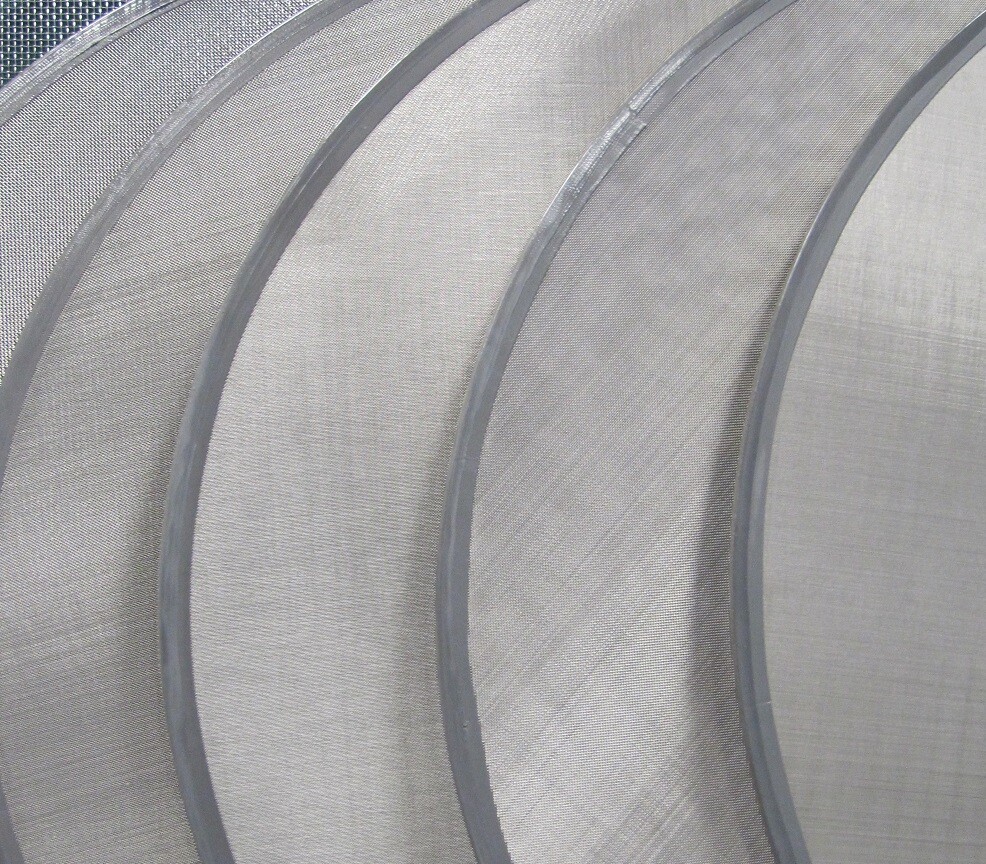

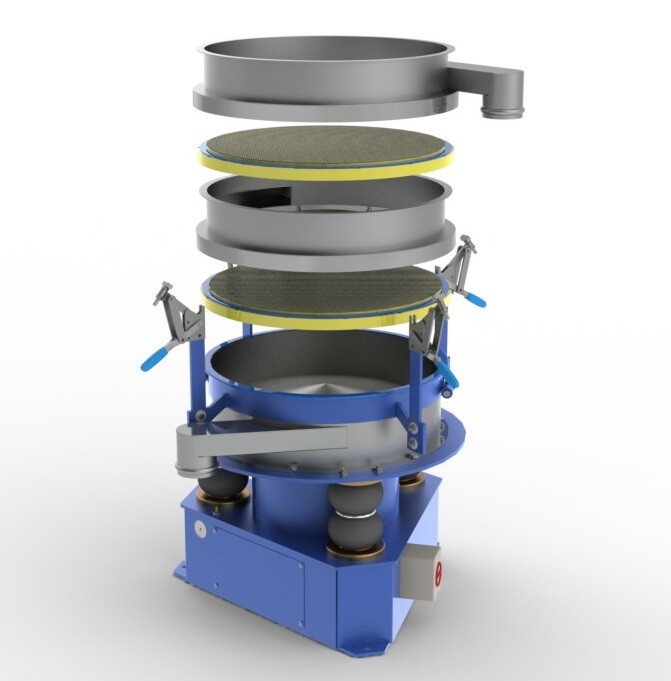

Sieve and screen separator parts

With over 5,000+ sieves and screens supplied and in operation, we know how crucial it is to have the right parts at the right time. Our spares and service manager oversees a comprehensive inventory of parts for various types of equipment and machinery.

Whether it’s a replacement part for a mechanical engineering system or specialised components for specific models, we’ve got you covered for.

- Meshes

- Motors

- Bellows

- Controls

- Deckware

- Top covers

- and more...

We supply spare parts for our sieves, screens and separators, including replacement meshes, motor components, and more, to ensure your separation equipment remains in top condition

Bucket Elevator Parts

For all of our customers we hold in stock or can supply many different types of elevator parts as used in many designs of our bucket elevators used throughout the world.

- Chains

- Sprockets

- Buckets

- Panels

- Controls

- and more...

Call today to find out more and how Gough Engineering can reduce the impact of breakdowns with superb delivery of those necessary parts.

Floveyor Parts

We provide a wide range of replacement parts for Floveyor aero-mechanical conveyors.

This can include:

additional and spare ropes and discs

motors,

head chute replacements

bearings

and many more...

helping you maintain efficient and reliable production capabilities.

Sieve re-meshing services

For many screening operations, one major consumable can be the meshes used within the machine.

Gough Engineering has its own re-meshing service

- Circular, rectangular or irregular frame design

- Standard single or ultrasonics frames

- Frame sizes up to 1,300mm

- Many aperture sizes available

- Bonded frame and conventional clamp type.

Call today to find out more and how Gough Engineering can reduce the impact of damaged meshes.

A focus on customer care, not just repairs

We don’t just show up when something is broken. Our goal is to support your business by preventing issues before they occur. Through our customer care health visits, we offer post-sales maintenance assessments free of charge.

By focusing on proactive maintenance engineering, we help our customers avoid the common pitfalls of based maintenance, where issues are only addressed after they occur. We believe in maintaining your equipment before problems arise, which is why we prioritise predictive maintenance and regular check-ups.

Quick and efficient support

When you need support, Gough Engineering is here to help. Our fast response times and easy-to-use support system make it simple for customers to get the help they need. We offer multiple channels for support, including:

- Direct contact with our service manager: Reach us by phone or email for immediate assistance.

- Scheduled maintenance plans: We’ll work with you to create a maintenance schedule that fits your production cycle, ensuring minimal disruption to your operations.

.

Long-term support

Gough Engineering is committed to building long-lasting relationships with our customers and we offer warranties on all our products.

Due to the longevity of our machines, the spare parts supplied by Gough Engineering ensure you continue excellent operational performance. We design and manufacture all our equipment as industrial, heavy-duty, and know the machines will survive continual batch processing or even continuous production 24/7. Gough have always maintained their heavy-duty designs and know, compared to the competition, our machines will provide decades of excellent service.

Contact us today

With our team’s maintenance engineering expertise, your equipment will always be in good hands. Gough Engineering’s proactive approach and commitment to customer satisfaction make us the ideal partner for all your machine maintenance and after-sales support needs.

Contact us today to schedule a risk assessment, arrange a maintenance visit, or learn more about how we can help keep your production running smoothly.

Health Check Checklist

See our checklist for particular machines to help in planning our support,