Industry: Plastics & Polymers

Over many decades the Gough patented Vibrecon vibratory separator has been widely accepted and utilised by many companies in the Plastics and Polymer industry. Its primary purpose is for accurate grade - and we can provide guidance on the type of machine for your operations and quality assurance. With Gough’s design, supply and long term parts/service support in the plastics and polymer industry we know we have it right and each solution is optimally designed.

Working with some of today's leaders

Quality

Quality can mean many things, but here its all about quality of raw materials or additional ingredients to manufacture to the standards you need. If its masterbatch, Gough Engineering can help...

Productivity

By automating a process, the flow of ingredients within your production will increase. Product will transfer from one process to another, occasionally automatically filtering out unwanted material to achieve final product quality levels with satisfaction.

Reliability

Superb build quality will provide a machine that will endure many years of operations. It's like Triggers broom, by changing the parts when needed, it goes on and on and on... See more about parts support on the link below.

Powder Manufacturers

If you are involved in manufacturing of raw materials for the plastics industries, Gough can help your company refine quality standards with vibrational sieving and screening machines and also moving materials with a variety of product transfer methods and schemes integration.

Whatever your powder production, if you require a small batch sieving operation, with ergonomically designed platforms for rip and tip station delivery, possible dust extraction then talk to Gough Engineering.

Masterbatch Manufacturers

Masterbatch production requires accurate application of a solid product (plastic, rubber or elastomers) in which pigments / additives are applied with a high concentration and dispersal into a carrier polymer material.

All within the processes of masterbatch operations including:

-

Selection & blending

-

Compounding & Extrusion

- Cooling, cutting and packaging

Whatever your needs, please contact Gough Engineering to discuss projects you think would benefit production.

How we can help

Our range of patented sieving and screening machines vary in design and use. The Vibrecon (GVC) pellet screener has been developed and used by many companies over decades, specifically for the separation and classification of pellets into the following particle sizes:

- Oversize, debris and agglomerates

- Middle fraction, usually classed as good product

- Fines and dust

This will produce consistence pellet sizes for further processing or packaging for the supply chain, reducing eventual production waste and improving efficiency.

For larger throughputs

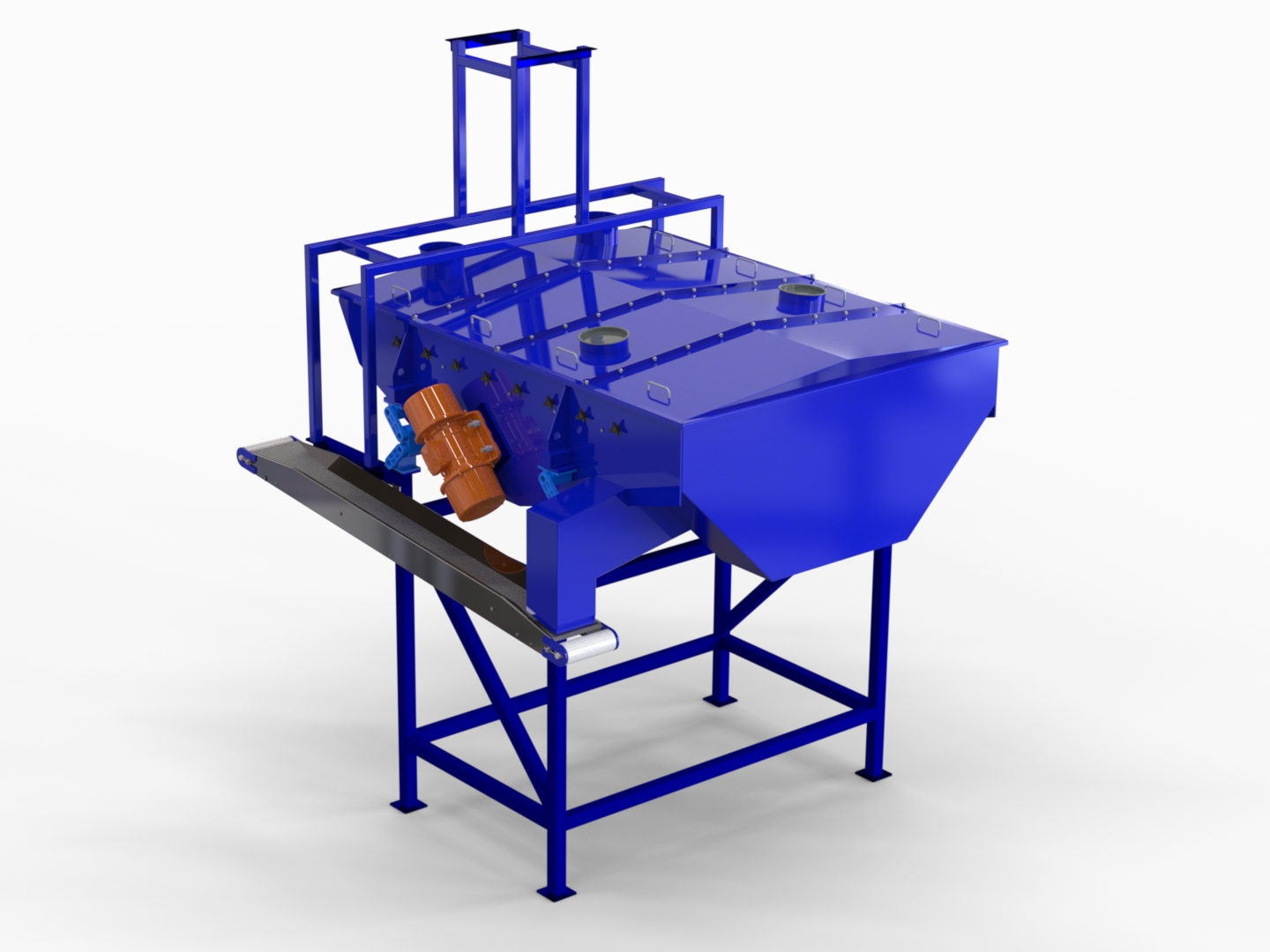

The Gough Linear Vibratory Screen (GLVS) is a rectangular screening machine, capable to deal with 1 or 2 fraction separation at high throughputs than the circular Vibrecon (GVC) machines. The strong twin out-of-balance motors produce more vibrational amplitude and screening area sizes (with machine widths of up to 1,500mm).

Gough have knowledge on pellet flow and use the correct designs in both circular and linear screen to ensure excellent classification.

Q&A

Here are some additional insights into the Gough machines and how we support the plastics industry. You can always reach us on the contact details below to discuss your projects, issues and thoughts.

Classification type?

The classification types can be the following types:

Two fraction

- oversize particles

- good particles

Three fraction

- Oversize

- Good

- Fines

Sizes of pellets?

Typically the size of pellets can be around 3 to 5 mm in diameter and lengths. But there can be small or larger varieties.

For conglomerates, meaning a number of particles stuck together, these are classed as oversize and normally are separated out to the individual particles classed as good.

Fines are broken pellets, shards or dust.

Parameters we need?

Gough Engineering apply a variety of calculation on your product pellets for us to determine the size of machine you need.

Product Name

Product Material (PP, PE, or others)

Bulk Density (kg/m3)

Throughput Feed Rate (kg/hr)

Feed and Discharge

It is always useful to know how the material is fed into the screening/classification screen. Let us know if it is:

Hand fed?

Continuously fed?

If continuous, can it be fed into the centre of the screen in a uniform and consistent manner?