Pellet Screeners

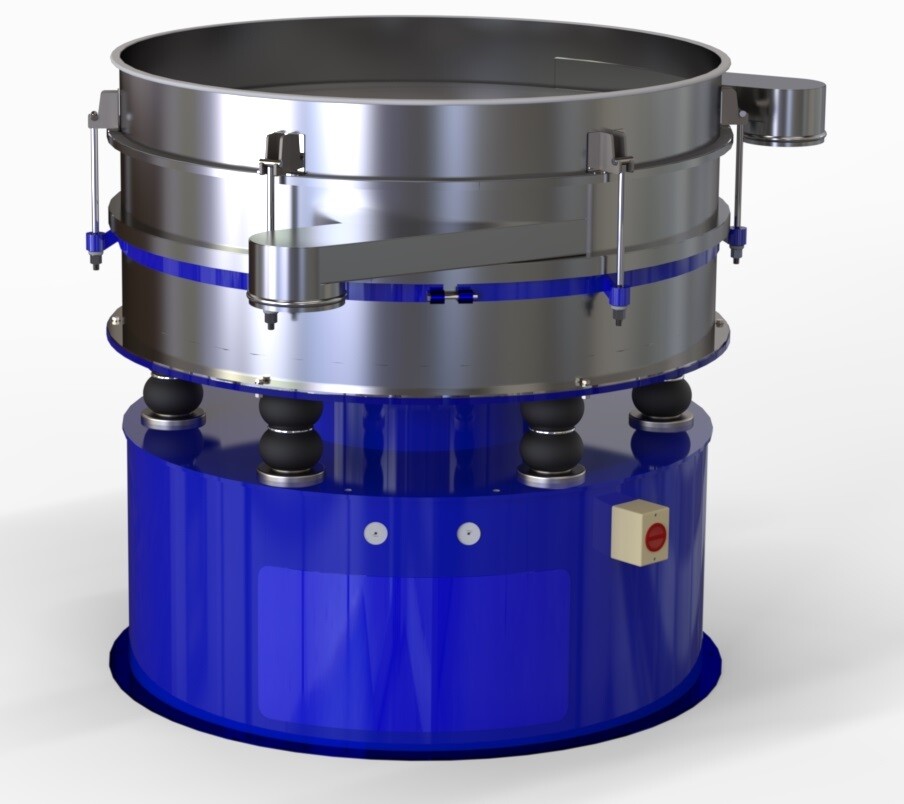

Gough’s circular Vibrecon Pellet Screen machines offer superior classification of plastic pellets with long life span and minimum running costs - securing your pellet sizing and quality assurance needs.

We continue to work alongside many leading plastic / masterbatch manufacturers.

Preservation

Screening and classifying your pellets is crucial, but preserving the materials integrity is even more critical, where the right solution will minimise the creation of dust.

The right way

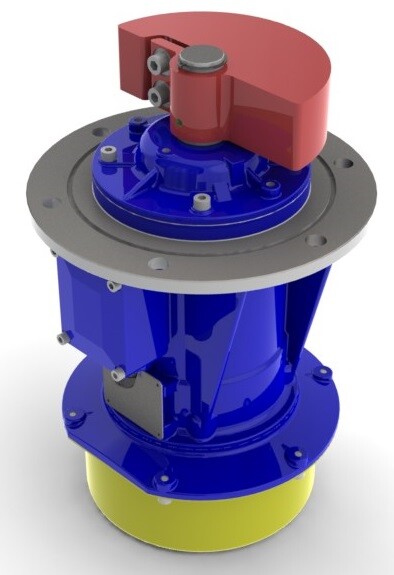

For long-term operations Gough uses the best vibrational techniques in the business using air bellows for vibration suppression & noise and the drive solution & weight settings - along with years of experience.

Features

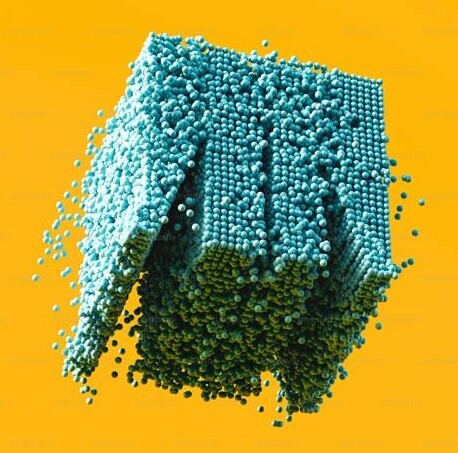

Even down to the right perforated plate and wire mesh surface features allow accurate classification of particle sizes, eliminating non-conforming sizes to give consistent pellet quality for manufacturing.

Introduction

Superb Separation

The Vibrecon Pellet Screener is an adapted version of the classic Vibrecon system, specifically designed for processing plastic, rubber and masterbatch pellets and granules.

The pellet screeners can be built up to remove oversize, undersize or both at the same time, separating out only the ideal pellets for your downstream production processes.

The system offers great reliability, guarantees thorough screening, and is available with special lowered deckware so the unit can fit directly below preinstalled pelletiser output chutes.

While we typically recommend circular pellet screeners, we are happy to supply linear pellet screening systems as requested.

Vibrecon Key Advantages

Accurate

Complete and accurate screening of all pellets are achieved, removing all oversize and undersize in one process.

Reduced downtime

The simple and robust design will continue to function with very little mechanical intervention.

Diameter range

Vibrecon Pellet Screeners are available in 24”, 34”, 44”, 54” and 64” diameters, meaning we can cater for all throughput requirements.

Long life

Our systems are the reliable choice, with some systems still in production after over a decade of service.

Punched Screening Plate

Instead of screening meshes, the punched plates give a smooth travel across the screening area, and the punched hole allows good pellets through more easily.

Air Bellow Suspension

Vibrecon Pellet Screens use a patented air bellow suspension system that gives a low noise operation and last far longer than conventional springs.

Durable & Long Servicing

These machine are built to last with decades in use across many industries, with a superb Gough part service when you need them.

Superbly designed features with the best plastic pellet separation in the business.

Also - Two sets of adjustable vibratory motor weights mean the screeners can be finely tuned for optimal grading and throughput.

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Contact us today

Want to find our more on our specific pellet screeners...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com