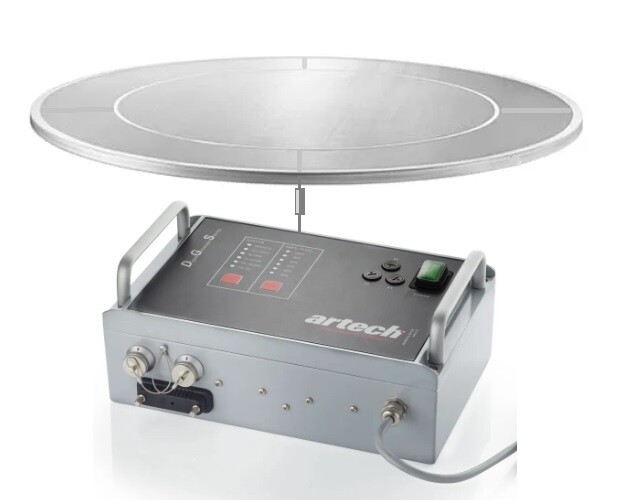

Vibracon® Vibratory Separator

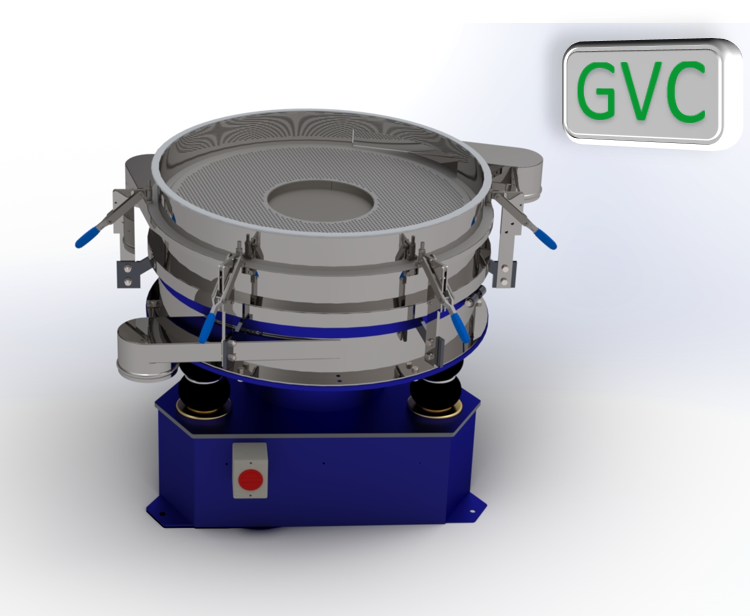

The Vibrecon Vibratory Separator (GVC) is a circular/rotary action separating and sifting system, designed for processing product on an industrial scale. It is a heavy duty solution with multiple fraction capabilities, very robust and easy to maintain.

Introduction

Super Screeners

Superb classification of your product materials...

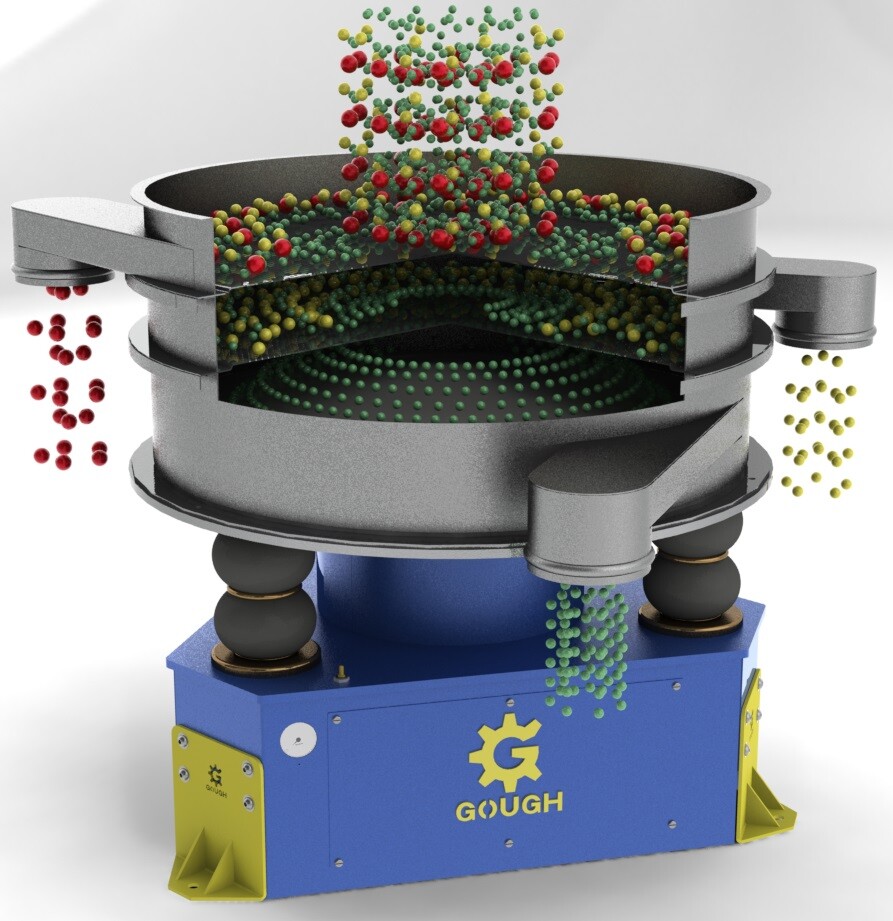

The Vibrecon® Vibratory Separator is a circular rotary-action separating and sifting system, designed for processing product on an industrial scale.

This Gough separator is a powerhouse solution in providing a separating and classification process for many types of material grading and can be utilised across multiple industries including Masterbatch plastic pellet classification. The system is available in multiple stacked or single screening deck configurations and comes in a range of sizes to handle varying throughputs.

The system uses a gyratory sifting action to continuously clear the screening area and encourages a high rate of throughput. Our separators have been used to process a wide variety of materials, and a range of optional extras means our systems can be tailored to suit your production requirements.

How it works...

Feeding

Material can be delivered centrally onto the sieve mesh manually or for example you can use a linear feeder for automating transfer (GLVS).

The Process

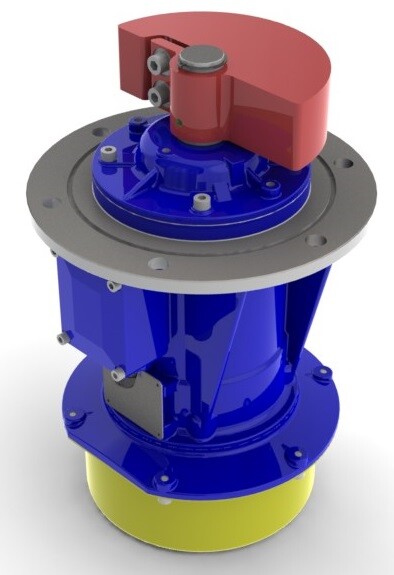

Through a single motor the screens are vibrated centrifugally and vertically with the motor weight settings. Oversize, middle good product and fines all flow through external discharge spouts.

Collecting or Conveying

All discharged product can then be deposited into containers or automatically feed onto transfer conveying systems like vacuum, aero-mechanical or vibrating feeders to the next process.

Options

A super range of options from ultrasonics, ball trays, extended spouts, base heights, top covers with inspection ports and more...

Key advantages of our separating machine

Industrial design

The Vibrecon is built to last. Industrial base, superb motors and unique vibration suppression using air bellows. It just keep going...

Superb classification

With the correct weight settings from the factory, the smooth gentle vibrating action gives excellent separation and classification of product material into the fractions you need for production.

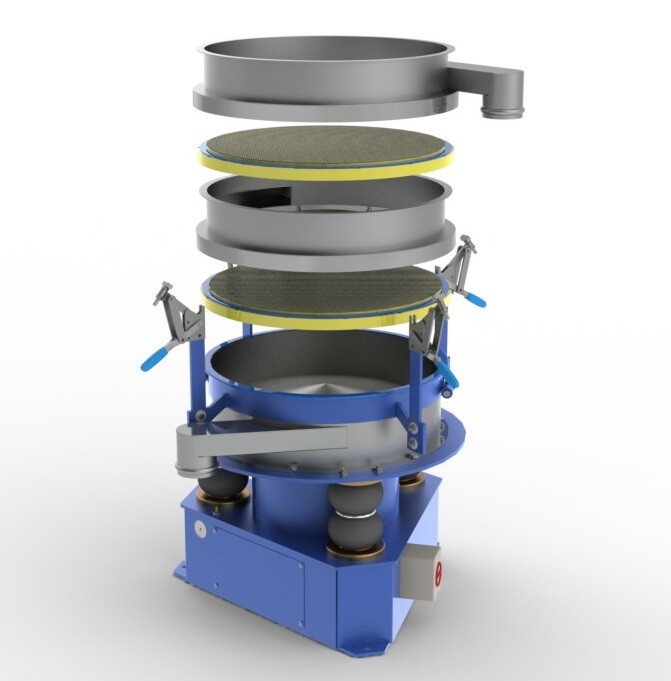

Quick changeovers

As with the Batch Sieve (GBS) the quick release clamps allow fast changeover of all parts. If you have clean standby mesh frames available, switching over can happen in seconds.

Super ergonomics

With a low noise level up to 73dB, access to all spouts on the outside, easy to clean surfaces we can supply the right machine for your operators and applications including liquids.

Vibrecon® Model Range

Model |

Screen Diameter (mm) |

Screen Area (m2) | Number of Meshes |

WM or PP Apertures sizes (mm) |

GVC 2 |

610 (24”) | 0.26 | 1/2/3 |

WM 0.3-12 PP 3-40 |

GVC 3 |

864 (34”) | 0.53 | 1/2/3 |

WM 0.3-12 PP 3-40 |

GVC 4 |

1,118 (44”) | 0.88 | 1/2/3 |

WM 0.3-12 PP 3-40 |

GVC 5 |

1,372 (54”) | 1.33 | 1/2 |

WM 0.3-12 PP 3-40 |

WM-Wire Meshes

PP - Perforated Plate

Enhancement Options

- Machine sizes to match your throughputs.

- Multideck configurations.

- Top cover with inspection ports.

- Mobility with castors.

- Flexible connectors to minimise dust.

.

Enhancements...

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Plastic & Masterbatch Pellet Screening

The Vibrecon doesn't just classify powders, its was designed for the plastics industry as a pellet screener...

Flipbook for screens

Flipbook for Transfer Systems

Contact us today

Want to find out more on our superb Vibrecon solution and all its benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Reach out to us

We have a lot to offer in implementing vibratory and full transfer systems within your production lines.

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

I need multiple fraction, how many screens can you have on one machine?

You can use the Vibrecon in many for fraction separations:

Single screen

A single screen can be used.

Multiple Screens

2 separate screens can be used to give three fraction separation normally classed as Oversize, Good and Fines.

3 separate screens can be used to give three fraction separation normally classed as Oversize, Middle Good #1, Middle Good #2 and Fines.

Can the machine be mobile?

Can I have top covers for feed materials?

Can I have longer discharge spouts?

Yes, addition spout lengths are possible, and length depends on the application and size of machine.

How does the material move on the screens?

The machine's out of balance motor, generates a circular, centrifugal motion for product material to move from the centre of the screen to the outside and perform its classification. There is also a vertical motion to assist in the material movement across the screen.

Note: Always pour the feed material into the centre of the top screen to maximise screening effectiveness.