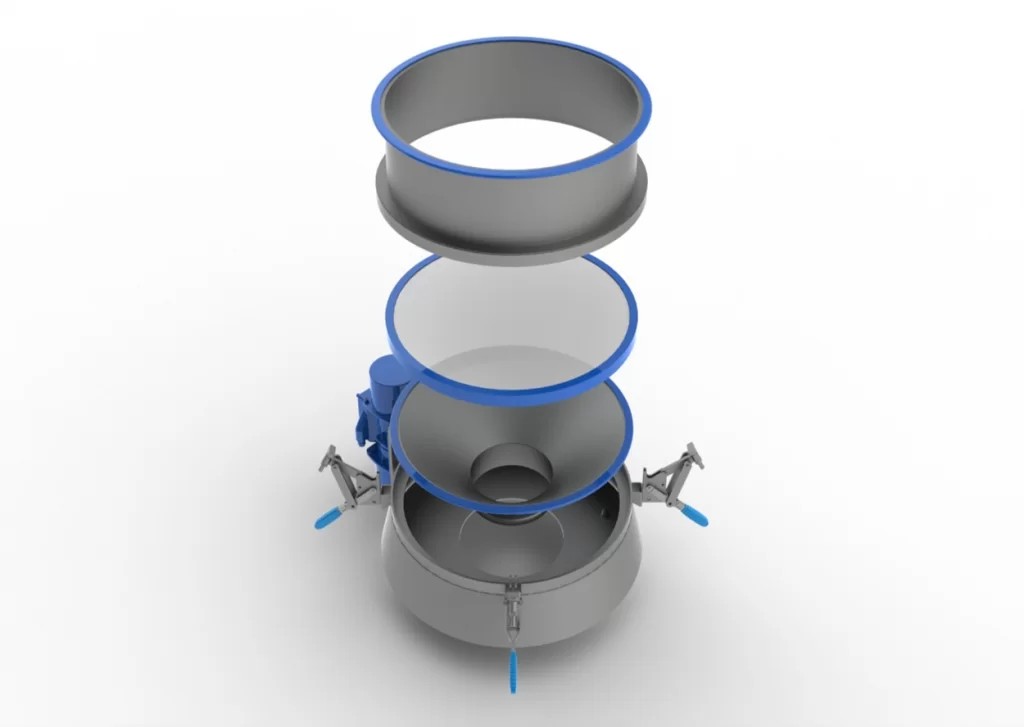

Magnet Separation

We combine special magnets solutions in Stainless Steel for the best separation of ferrous contamination from product material such as powders. We design the position of the magnet suitable for whatever sieves, screening or separation machine you are looking at.

They come in many types from single or double row, fixed or removable.

Removing Ferrous Debris

Ferrous metals can be removed with the correct magnet field strength between 7,000 and 10,000 dependant on product material and throughputs.

Easy Clean Design for Hygiene

Superb magnet designs with smooth surfaces, high quality finish and Stainless Steel finish of 316. Fixed or easy cleaning removable designs can be offered.

Single, Double or Triple

Magnets designs are selected on suitability with multiple levels if required. Single row or the most common, but double magnets rows and even triple can be implemented.

Where to place it?

The magnet can be positioned in the following ways:

1) pre-screening positioned above a top cover so its removes ferrous from all feed product.

2) post-screening positioned on the outlet spout of the good product material only.

3) Built within machine as they easy to clamping system, so you can access and clean within seconds.

Contact Us Today

Want to find out more on our magnetic options...

Call our sales team to discuss your requirements on:

+44 (0)1782 657770

Heading

Find out more about our Batch Sieves GBS with either 550mm or 850mm diameter screen sizes.