Automation in food production can be crucial to keep up with demand. This case study shows how Gough Engineering designed and supplied the right continual elevating and feeding equipment for their correct cereals material handling.

The Task

A large cereals manufacturer based in Yorkshire, a European market leader, required a food conveying, elevating and feeding system to connect the production and packaging sections within their operations. As with all systems of this nature, the flow and directional requirements were unique to the clients operations.

The Solution

Four Bucket Elevators were commissioned to move a range of cereal products at a rate of 1,000 kg per hour. The Gough Linear Feeders that are fed via Big Bag Stations deposits at a rate of 500kgs per hour and are also functioned to screen the chocolate coated cereals for abnormally sized pieces of cereal, that can then be fed into a separate system. The interconnecting Conveyor System was nominally set at a speed of 18m per minute.

The Food producer has used Gough Engineering for a number of years at multiple sites as Gough’s reliable and cost effective machinery, accompanied with 24/7 spares and service support, make Gough a safe choice.

This superb example of how Gough's core product range including feeders, screens and elevators all working together to achieve a desired throughput and flow into the packaging line.

The Result

Gough has many years of handling cereals from sugar coated cornflakes to muesli and oats. As maintaining product integrity and a good flow rate are paramount in the production of cereals, which Gough can ensure both with its range of interfacing materials handling equipment.

As you can see from the image below, the elevator vertical height of 9 meters sits next to a large support frame where the linear feeder sits on the first floor of the frame, guiding materials in a controlled manner into the bagging / packing station. This Series 'S' Swinglink elevator was supplied with a fixed end-over tip discharge and as you can see, a hinged panel with a viewing window, interlocked/sealed for maintenance is included in the elevator specification.

Gough Engineering

Founded in 1940, Gough Engineering continues to design, fabricate and supply a variety of sieving, separating, classifying batch sieves, Vibrecon® and Vibraflo® trademark vibrational machines and also material transfer solutions including the superb Swinglink® pendulum bucket elevators and vibratory feeders for many applications and industries. Based in Stoke-on-Trent, Gough's competences encompass conceptual to full engineering designs, its own modern welding and fabrication facilities and comprehensive stock of Gough's equipment parts and technical support for excellent customer service.

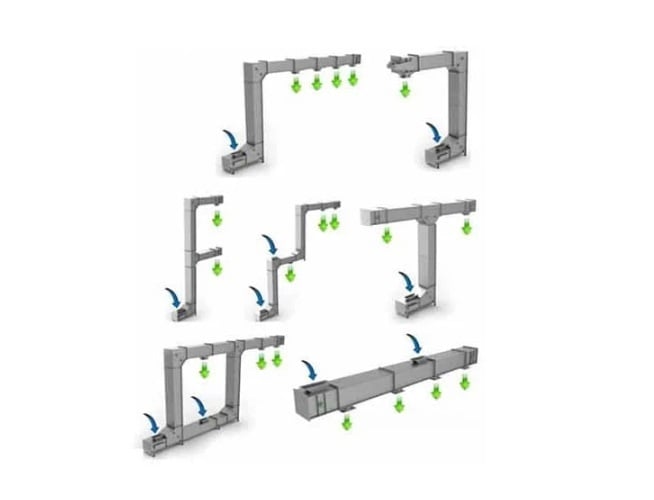

Different Elevator Designs

Each application is different in designing the correct elevator, which includes the type of product material being handled, its properties during movement, the distances to be covered in the lower section, vertical and upper section. Each section can have multiple inlets and outlets that feed multiple post-process production lines. Whatever your requirements, we can review the elevator suitability and benefits of using it to convey product safely from one location to another.

Related Products

Gough Swinglink Bucket Elevator (GBE)

Introducing the configurations and design elements of a bucket elevator, a crucial piece of equipment to move product from one location to another without degrading the product state (suited to all types of fragile product used in the foods, pharma or chemical industries) and ensuring no loss of product as it traverses the required distances - which may require multiple inlets and multiple outlets. The Gough Swinglink solution is the best material handling for food

Vibratory Feeder (GL:VF)

Vibratory feeders allow the controlled movement of product from one location to another using a single tray surface. The vibration can be generated by different drives and is normally required to generate a smooth continuous flow of material from one process to another. If the tray does have a scree built into the tray this would be called a vibratory screen.

Big Bag Discharger (GBB)

The Gough Big Bag Discharger (and also Fillers) are used to reduce the manual handling using small bags (20-25kg) and allows a controlled efficient flow of material from a single or different sizes of big bags. The designs come in many forms for holding the bag as well as the untie chambers and flow control measures Gough can implement.

Parts and Service

The parts and service department has always maintained an excellent client and customer relationship, bringing technical advise as well as the quick supply of spare parts from our in-house stock management.