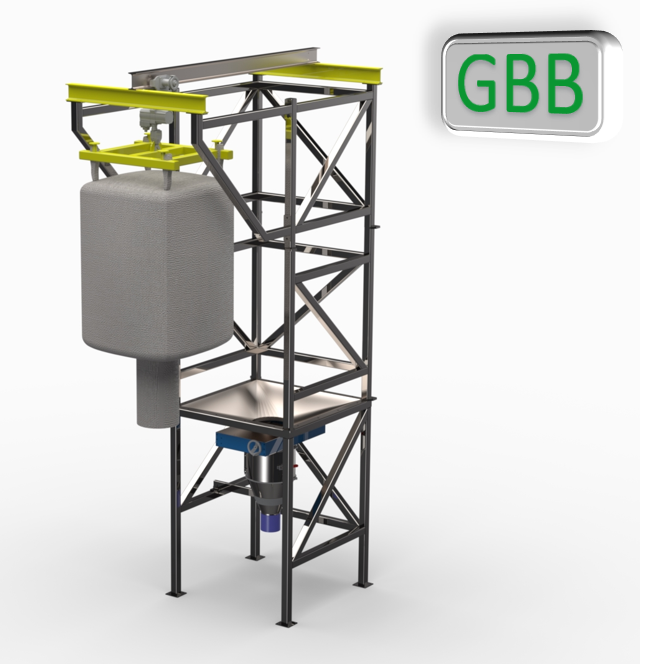

Big Bag Handling

FIBC Gough Big Bag (GBB) Dischargers are machines that safely unload bulk materials from large, flexible containers called FIBC bags or super sacks. These durable dischargers usually have a frame for support, a hoist, and a chute. The design allows a bag to be lifted and moved into position and controls the speed at which to release material.

Introduction

FIBC Big Bag Discharger systems are crucial in various industries for cost-effective and safe material handling, enhancing efficiency.

They swiftly unload fertilisers, grains, and seeds in agriculture material handling, enabling efficient distribution. In food processing, we handle powders and ingredients carefully to maintain product quality and prevent the release of fine particles.

The pharma sector relies on them in pharmaceutical discharge systems, for contaminant-free release of active ingredients, ensuring stringent quality control. For construction material handling, these dischargers streamline the handling of cement, sand, and aggregates, optimising workflows. FIBC Big Bag Dischargers help chemical manufacturers safely unload different compounds without dust, meeting their needs for secure big bag unloading and discharging.

Find out more on Linear Feeders...

How it works...

Feeding

We can design cruciforms to lift bag using a forklift, or you can have an integrated operator hoist/ pendant / cruciform solution.

Discharging - no dust

Bags can be untied by the operator using a safe untie chamber with access door. Product flow can controlled with slide gates, shutoff valves, gravity feeding down into smaller bags or conveying equipment.

Conveying

Small hoppers like the shown here, allow product to be released from the big bag and continually fed into vibratory feeders.

Bespoke

Design for any type of bulk handling solutions, Gough can guide you on the best approach, safe and industrial design for long term operations.

Key advantages of the Big Bag Station

Reduce product loss

Integrated chutes guide product from bag to receiver, preventing any loss.

Dust containment

The chute section envelops the lower outlet of the FIBC Big Bag, effectively preventing dust emissions.

Contamination prevention

The enclosed chute section acts as a barrier, safeguarding against potential contaminants from entering the discharged product.

Enhanced safety

The secure handling of large, heavy bags significantly improves overall safety protocols.

Safe handling

Using correctly rated hoists and pendants, or forklift crucible designs will provide operator safe handling.

%20Discharger%20is%20shown%20here%20as%20an%20equipment%20scheme.jpg?noresize&width=1050&height=1400&name=The%20Gough%20Big%20Bag%20(GBB)%20Discharger%20is%20shown%20here%20as%20an%20equipment%20scheme.jpg)

Enhancement Options

Big Bag handling options can include:

- Single or multiple big handling frames for faster multi-bag operations.

- Full , semi or partial bag frame designs for low headroom.

- Integral hoist, beam and pendant controls.

- Forklift cruciform docking station frame design.

- Large box section, sturdy design, long lasting.

- Enclosed untie chamber for releasing bag ties safely.

- Discharge without creating a dusty environment through proper containment.

- Fully compatible to suit all types of bags with difficult flow properties.

- Agitation systems possible with paddles or motor vibration.

- Flow control with pneumatic valves.

- Integrated automated conveying system using vibration, aero-mechanical or vacuum methods possible through Gough Engineering.

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Lavazza's triple big bag discharging stations by Gough Engineering

At Gough Engineering, we're proud to have continued our partnership with Lavazza, a leader in the coffee industry, by delivering cutting-edge bulk handing system.

Contact us today

Want to find out more on our Big Bag solutions and safety benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Reach out to us

We have a lot to offer in implementing bulk handling transfer systems within your production lines.

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

What types of hoist are possible?

One can utilise either electrically powered or pneumatically powered hoist (used in certain ATEX zones requirements)

Bag sizes are all different, how do I move forward?

If your bag sizes are different, we can design a system to accommodate different lengths, widths and heights.

Some bags are not necked at the bottom - how do I discharge?

Gough Engineering can provide solutions for bags with or without necks to discharge from using bag blade opening technologies and untie chambers to suit.

My material is difficult to empty?

This is where agitation system are needed. We can provide small agitation using vibrational electrical motors or the larger paddles, moving the base of the bag in each corner to release product down.