Linear Vibrating Screens

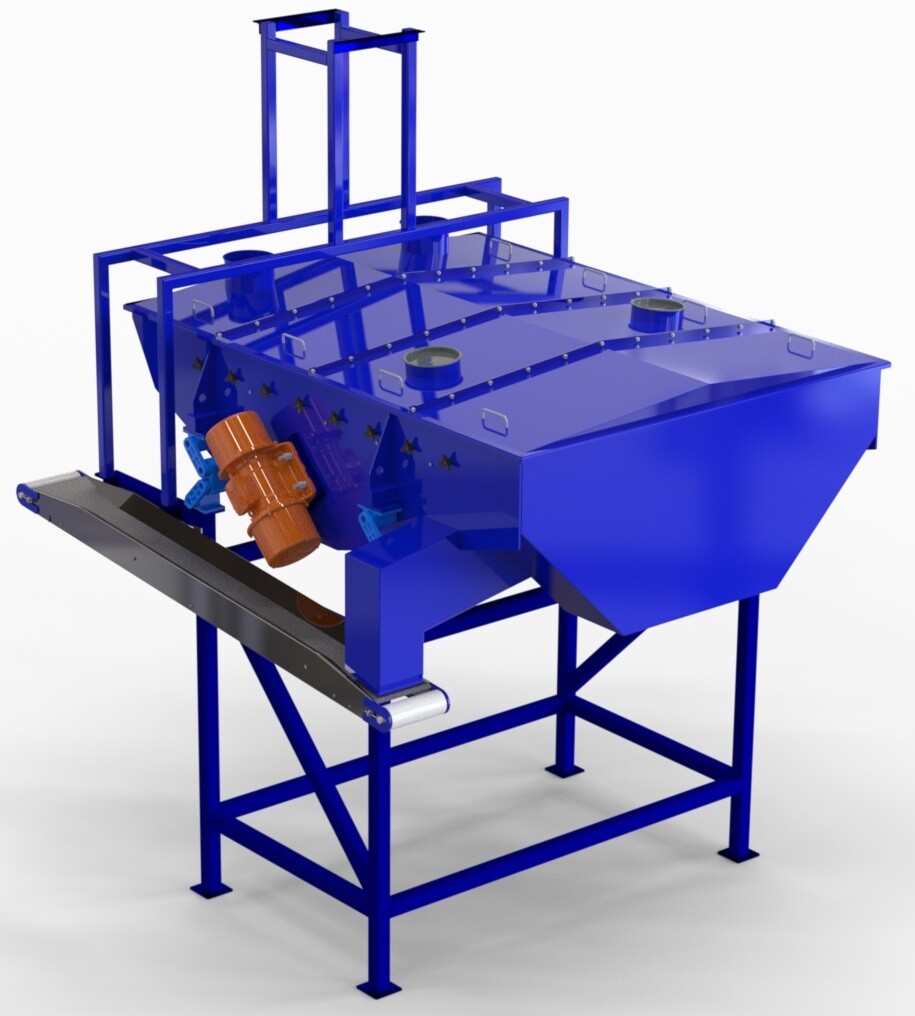

Gough Linear Vibrating Screening (GLVS) machines are suitable for light or heavy-duty applications. They are capable of handling high rates of throughput and separating bulk material into multiple fractions normally oversize/fines or oversize/good/fines from a continuous product flow. The sizing of the screen area is design to match your throughput rates with excellent vibration bounce using large efficient motors The decks can be either wire mesh, perforated plates or bars type design depending on the application and product material to be classified.

Introduction

Superb effective screening whilst moving

Gough linear vibrating screens (GLVS) are suitable for a range of different processes, including:

- Extracting fine particles or dust

- Removal of oversized particles, lumps and agglomerates for a more uniform consistency.

- Conveying a distance whilst screening between production stages.

We design and manufacture all our linear vibrating screens to order. We offer screen sizes ranging from 200 – 2,000mm wide with tailored screen decks for easy maintenance.

Our linear vibrating screens have been used across many industries including foods, plastics, chemicals and scrap processing. All support frameworks and discharging can integrate with other transfer systems from Gough Engineering.

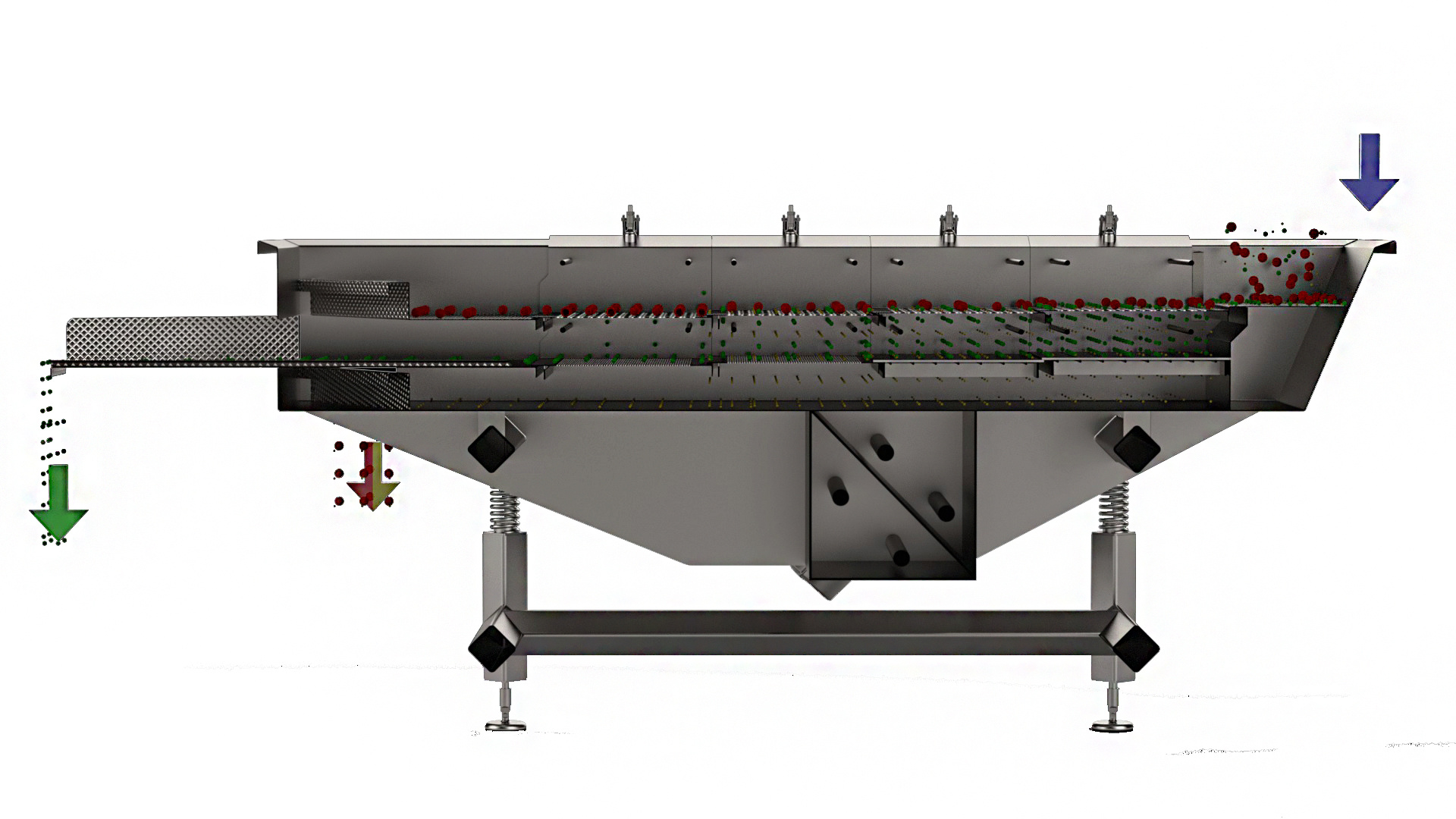

How it works...

Feeding

Material can be deposited onto the sieve mesh by manual means or conveyed using conveying techniques like conveyors with special in-feed trays.

The Process

Using the powerful twin out-of-balance motors the screen or screens will separate oversize (remaining on-top of the mesh) from finer good or fine product material flowing through the each deck to an specific outlet spout.

Collection or Conveying

Each fraction of material (oversize/good/fines) can then be collected into bins, big bags, or conveyed onto the next automated process like forming or bagging lines.

Bespoke design

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Key advantages of our linear machine

Heavy duty

The industrial design allows continual operations and separation of product material with high throughput rates if required.

Good vibrations

Superb, large sealed motor designs rated to the type of applications and production rates you need.

Screen type

We offer the following types of screens including: market grades (MG), Laser cut or perforated plates, Wedge wire and Grid bars.

Options

From top covers, ball trays, additional conveying units, special Rosta type mounts instead of springs for safe vibrational dampening and support frame connections.

Linear Screen Options

- Selection of stainless-steel screen mesh or perforated plates to tailor your machine to your requirements.

- Gough retaining hook screen design allows easy switching of screen mesh and perforated plates, without the need for frame or unit disassembly. without any frame or unit disassembly.

- Used in many different industries and applications.

- Top covers confine dust and particles to safeguard against contamination.

- Enhanced mobility and ease of movement with castor mounting.

- Ultrasonic and mechanical de-blinding systems to prevent blockages and reduce downtime.

- Tailored design available.

Enhancements...

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Better quality control in dried pet food

A company wanted to check screen their final dried pet food product before bagging...

Contact us today

Want to find our more on our fantastic linear vibrating screen solution and all its related benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

Tight spaces, can the design change?

Yes, the motors which normally sit on the outside, can be slung underneath if required to minimise the machine width. Whatever your constraints, let us know at the consultation stage.

Can meshes be swapped over?

Yes, meshes can be removed, cleaned or replaced by other types of mesh apertures for your production requirements. Both top and bottom screens are held using hookscreen rails and are easily adjusted without tooling.

Can top covers be design for extraction?

Yes, top cover designs are bespoke and can incorporate exist points for attaching to an extraction system to remove fine dust particles.

Can the support frame be designed for my application

Yes, all support frame can be designed to suit your application and to fit into the process both up and downstream. Also, support frames can provide additional adjustment to decline the linear screen to aid in product movement across the screens.