Sieving Flour to help improve quality

We have a super history in supplying the right sieving operations for bakeries and food manufacturers. Our range of sieves and respective options provide a complete sieving operation that's not matched by others especially combining and integrating specialised extraction product material transfer solutions.

...and with the ultrasonics package can provide automatic de-blinding of the sieve's wire mesh to keep your quality assurances.

More on Sieving at your bakery

Elevate your bakery with advanced sieving technology by Gough Engineering.

Call us on +44 (0)1782 657770

Email: contact@goughengineering.com

Read more on how to enhance your baking by clicking on this button below.

And you can also find out more on specific bakery Sieving Gough solutions by clicking the bottom below...

Flour Product Range

.

Hire me...

Why not try our hire of batch sieves for your operations and see just how good your quality can be improved.

Transfer Options

If you then need to move your material after sieving you can do this using a variety of methods, especially for elevation into you mixers, or holding bins.

Or if you have your own thoughts contact us to discuss.

Contact us today

For baking and food manufacturing, we are always here to help in quality screening applications.

Why not have a chat with our Team and find out the best approach.

+44 (0)1782 567770

Q & A

For screening product material in the baking and food industries especially with flour, Gough Engineering can assess your:

- Operator manual handling needs.

- Ripping and tipping operations with appropriate heights.

- De-dusting with partial or fully integrated extraction to keep operations clean.

- Correct sieve size.

- Mobile units.

- Feeding and transfer systems.

What are the benefits of a bakery sieve?

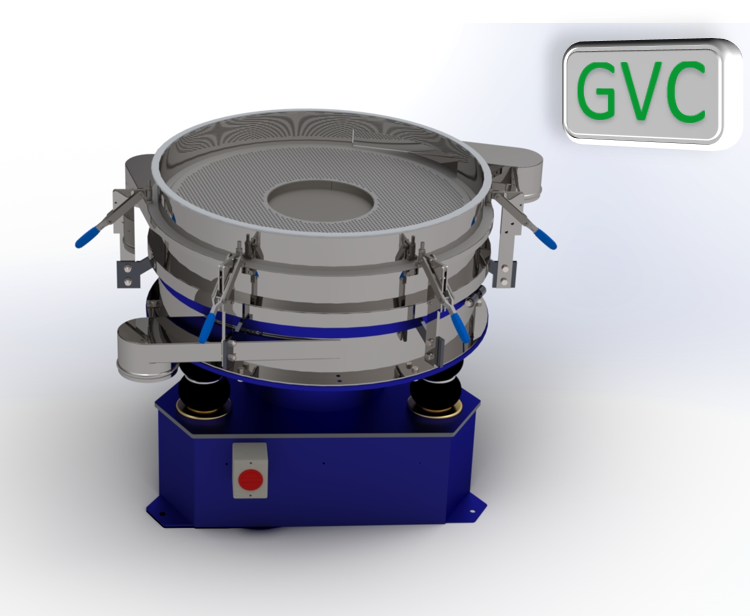

The Gough Batch Sieve (or Bakery Sieve) has been used in companies for decades.

The compact and easy to clean features (including seconds to strip down components and reassembly) allow this unit to be an extremely useful, simple sieving process.

It ultimately keep your quality assurance to the standard you need to for your supply contracts or production requirements.

How does the machine work..?

The sieve uses a single electrically powered small, efficient motor to generate a vertical vibration of the mesh screen.

The good (fine) material flow through the mesh and oversize (debris or large conglomerates) remain above the mesh.

The machine can be kept on for hours of operation with either manual or automatic feed of product material into the sieve.

Material Flow - how does that work?

The contents from a bag or bin can be poured by hand by operators, into the sieve.

The material is kept on the mesh, vibrated and the material with particle sizes below the aperture of the mesh e.g. 1.0mm fall through the central outlet spout underneath.

Oversize can remain ontop for manual assistance, or if you need the oversize to exit automatically we can supply an outlet discharge spout and hood for this requirement.