Spider Frame

Sometimes you may need to fill bags, not just discharge them. If you are feeding from existing machinery, or from one of our separators, to automate the process we employ the Spiderframe solution. It allows for product flow automation into 1,2,3 or 4 bags of any size.

Introduction

Simple & Effective Bag Filling

Gough Engineering is always challenging accepted methods and keen to develop better material handling equipment designs in a world of ever changing customer requirements to achieve better operations performance.

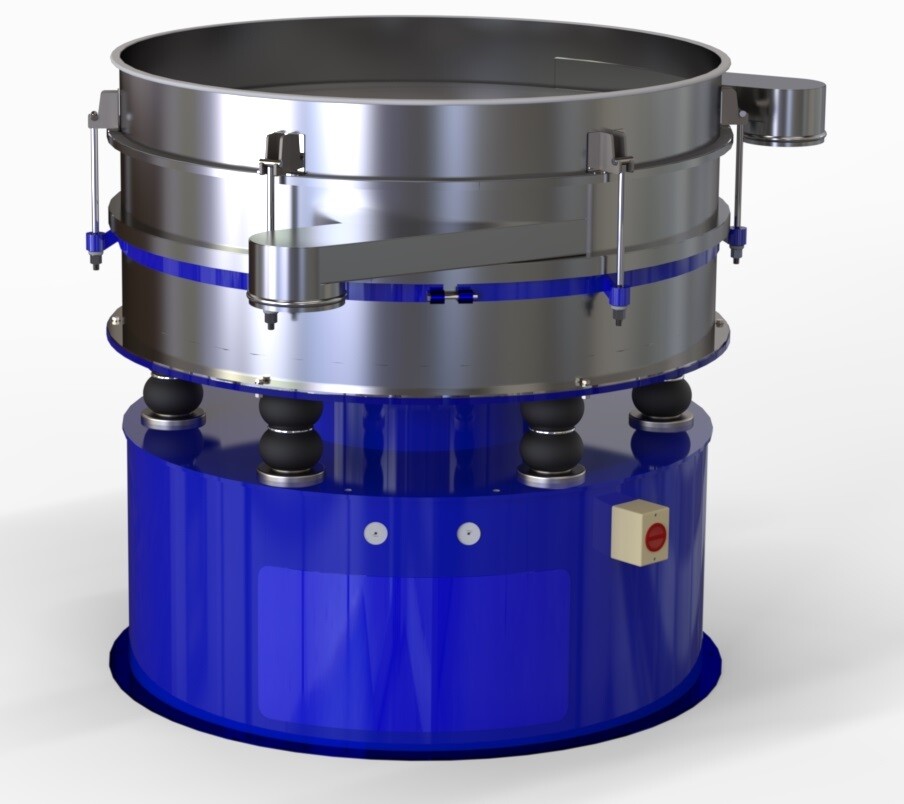

The Gough SpiderFrame is a new solution for applications where there is a need for 3 fraction separation and collection in one unique unit.

It utilises the outstanding Gough Vibrecon® Vibratory Separator, a unique support frame with a choice in receiving bag sizes tailored to your requirements.

What spurred this on?

In 2021, Gough’s design and engineering team produced a unique solution for a customer in the UK – the Vibrecon SpiderFrame. It combined out-of-the-box thinking and practical engineering knowledge to identify the best solution.

It allows a Gough Vibrecon Vibratory Separator to sit off the floor with the exiting spouts directly allowing material to flow over 1, 2 or 3 Big Bag fraction arrangements. This can be designed specifically for your needs.

Bolted to the floor or deck steelwork, the SpiderFrame allows the bags to retain their full shape as materials flows into them from the separator. Forklifts can then remove the Bags from the frame as and when required.

Where applicable a big bag discharge system can deposit directly into the Vibrecon and then separate into the individual big bags.

Key advantages

Reduced Waste

Hoppers are a simple and effective method of preventing product spillage and saving time on cleaning.

Cost effective

Product hoppers are often a low-cost addition to larger pieces of equipment that can greatly improve usability.

Flexible solution

Hoppers are simple to add to new designs and can be installed as a retrofit solution when production issues crop up.

Easy Maintenance

No tools needed to strip down. Just release the clamps, disassemble, clean and replace parts within minutes.

SpiderFrame Options

- Product flow into 1, 2, 3 or 4 bags.

- Direct feed from Vibratory sieves, screens or separators of any type.

- Auto bag filling reduced manpower.

- Less forklift work with simultaneous bag filling.

- Bag filling or conveying to next process can be integrated into the arrangement.

- Additional support frame easily mounted to sieves or separators.

Working in conjunction with...

Contact us today

Want to find our more on our unique spider-frame and more tailored handling solutions...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

Can a control the flow from one bag to another?

How many bags can I fill

You could have 1, 2, 3 or 4 bags positioned around the separator. But more bags can be arranged with correct transfer conveying schemes.

.jpg?noresize&width=675&height=540&name=Gough%20Linear%20Screen%20GLVS%20(Declined).jpg)