Starting in the early 1990’s our customer developed and produced live bacteria supplements for use by vegetarians and in the equine healthcare market as probiotics. Fast forward to today and they are at the forefront in development and innovative research of medicinal probiotics (pharmabiotics) for the human health industry with a well-known range of products found in most pharmacies and chemists.

The Task

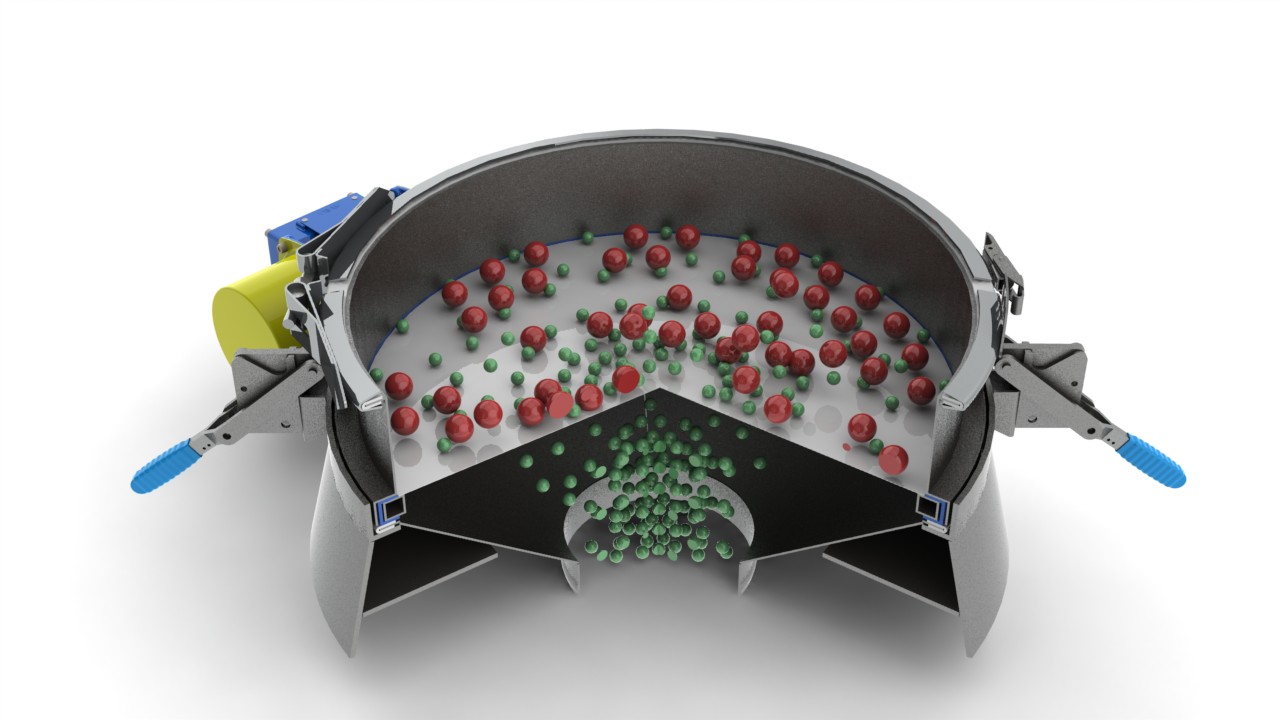

Nearly all probiotics formulations require some form of powdered additive and, as Gough are the UK’s leading manufacturer and supplier of material classification equipment, the client naturally made contact with us. Their new ‘state-of-the-art’ production facility for probiotics has a high care production environment and has two atmospherically controlled materials handling rooms. Our brief was to provide a ‘turn-key’ solution within each room for the screening of product into their existing IBC 1200 Pharmabins. Material would be supplied in bagged form and be required to be opened by hand and tipped onto the sieving deck.

This would require the design of an access platform for the vibratory sieve elevated to allow discharge of product into the IBC Pharmabin. The Pharmabin would also require a docking station and an inlet connection to ensure that the Pharmabin inlet consistently positioned itself beneath the sieve discharge point without product spillage.

The Result

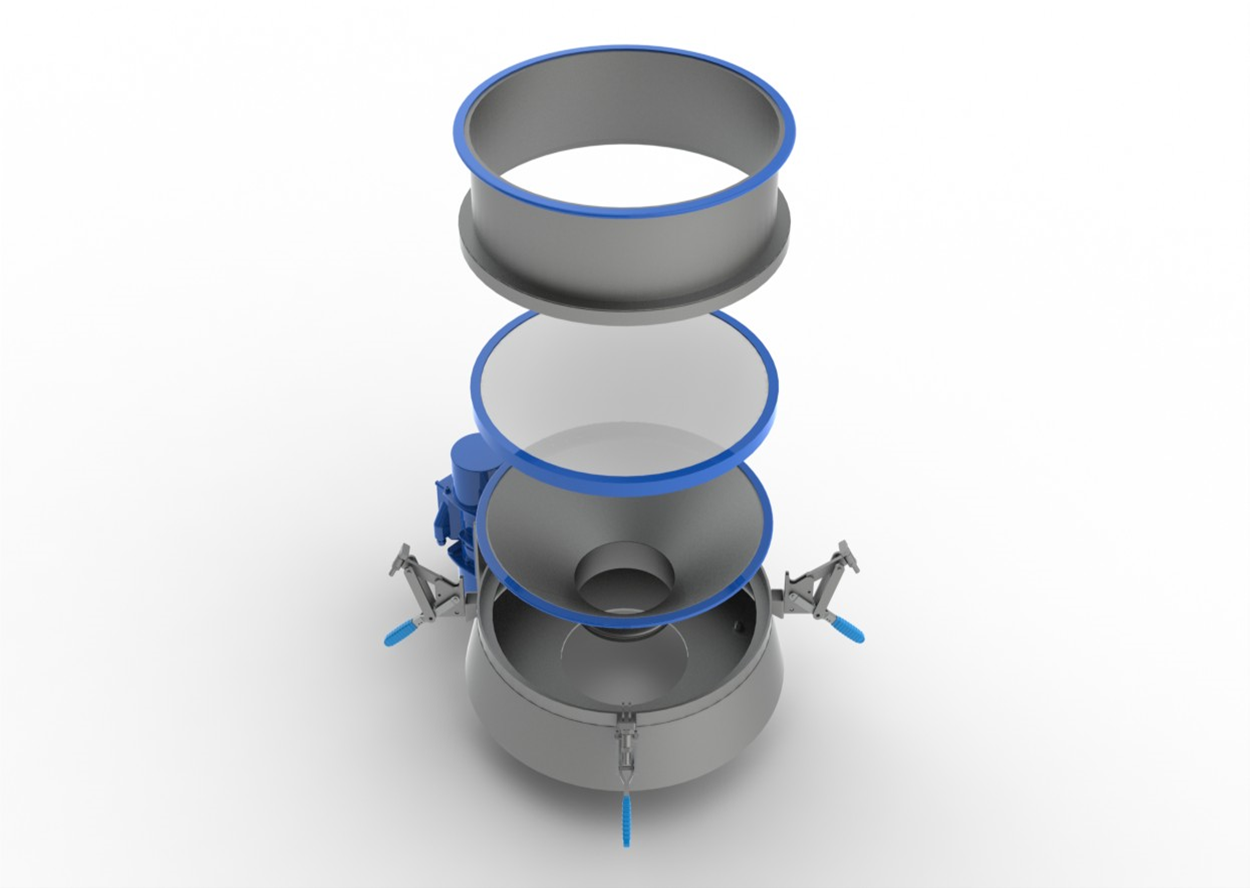

As the design brief was very detailed, a period of design consultation took place after which a formalised design proposal was submitted and accepted. The main sieving station would be a Gough GBS 850 Batch Sieves with single motor drive with quick mesh access for ease of cleaning and changeover.

The platform structure required to support the GBS850 Batch Sieve would be of stainless-steel construction incorporating a stairway and handrails. All ‘free space’ beneath the structure would be enclosed in white wall cladding as typically seen in a high care environment. The platform walkway would be 1200mm from the floor with the Batch Sieve raised to give access beneath for the IBC1200 Pharmabin.

As the material is supplied in bag format, we also incorporated a hinged rest area that could be utilised when a heavy bag needed to be supported whilst opening and stowed away when not required. An ingenious docking station and flexible inlet connection were designed to ensure correct loading of the IBC.

The installation took place over a period of five days, encompassing both areas, utilising one of our two-man installation teams. The customer then embarked on a period of trials to ensure all products sieved correctly and that the design brief had been fulfilled. The process and installation were signed off within a two-week period as 100% successful.

Our knowledge and resources enables a complete solution to be provided to the customer. Find out more about why large batch sieves are so critical to consumption industries here.

Contact Gough Engineering Today

If you'd like to find out more about the range of products that Gough Engineering can provide for your industry, then do get in touch today.