The UK nutraceuticals market was worth USD 5.55 billion in 2023 and is forecast to reach USD 8.36 billion by 2029 (CAGR ~6.9 %. Globally, the sector already exceeds USD 590 billion and is projected to grow at ~7.6 % annually through 2030. Source:

This growth is being fuelled by rising demand for fortified foods, dietary supplements, and functional beverages. Consumers are looking for clean-label, science-backed products that support long-term health. For UK manufacturers, the opportunity is clear — but so are the operational pressures.

Producing nutraceuticals means dealing with powders, botanicals, and active ingredients that are more difficult to handle than traditional food products. Systems must ensure dosage accuracy, prevent contamination and potential product cross-contamination, and maintain throughput, all while meeting EFSA and UK food safety requirements.

Three Production Pressures in Nutraceutical Manufacturing

Behind the sector’s rapid growth lies a set of practical challenges that every nutraceutical producer must address. From powders that don’t flow as expected to active ingredients that lose potency under stress, production teams face constant pressure to balance throughput, quality, and compliance. The most significant pressures can be grouped into three areas:

- Powder flow and blending

Most nutraceuticals are built around fine powders. These are prone to dusting, clumping, and flow interruptions, which impact blend consistency and downstream processes. Achieving uniform particle size and reliable flow is essential for accurate dosing and product quality.

- Sensitive active ingredients

Botanical extracts, probiotics, and enzymes can lose effectiveness if exposed to heat or mechanical stress. Conveying and screening systems must handle these ingredients gently to preserve their functional properties.

- Compliance and traceability

With EFSA regulating claims and consumers demanding transparency, manufacturers must prove that their processes are hygienic, consistent, and allergen-safe. Equipment must be food-grade, easy to clean, and designed to minimise contamination risk.

How Gough Engineering Supports Nutraceutical Production

With over 80 years of UK manufacturing expertise, Gough Engineering designs and manufactures nutraceutical powder handling systems that solve the core challenges of consistency, hygiene, and compliance. Our equipment is built for fine powders, botanical extracts, and sensitive active ingredients used in supplements, fortified foods, and functional beverages.

Vibratory Sieves and Screens for Nutraceutical Powders

- Maintain uniform particle size and dosage accuracy in powder blends

Remove oversized particles, clumps, and contaminants before tabletting or packaging

- Stainless steel, hygienic designs to meet UK and EU food-grade requirements

Gough Vibrecon® Machine

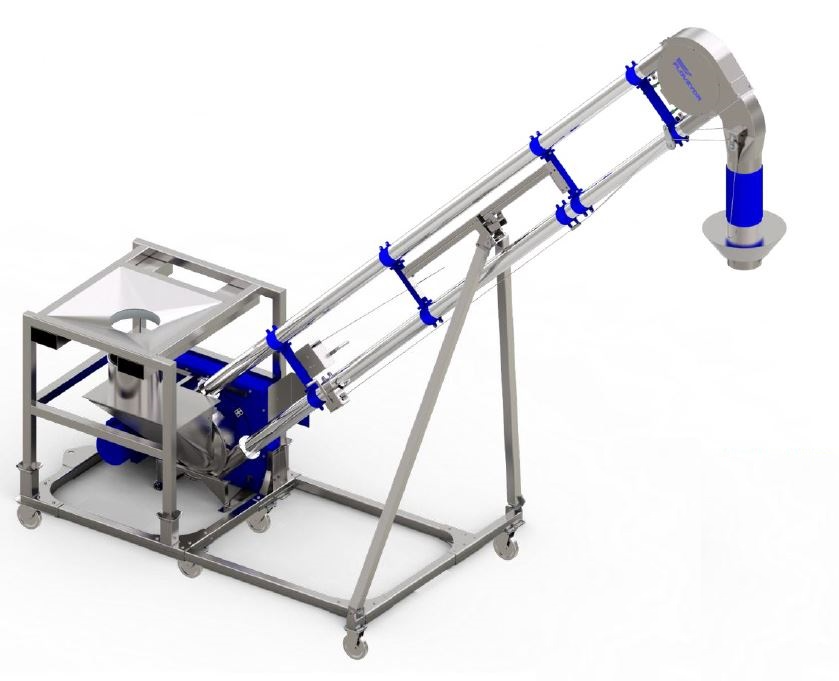

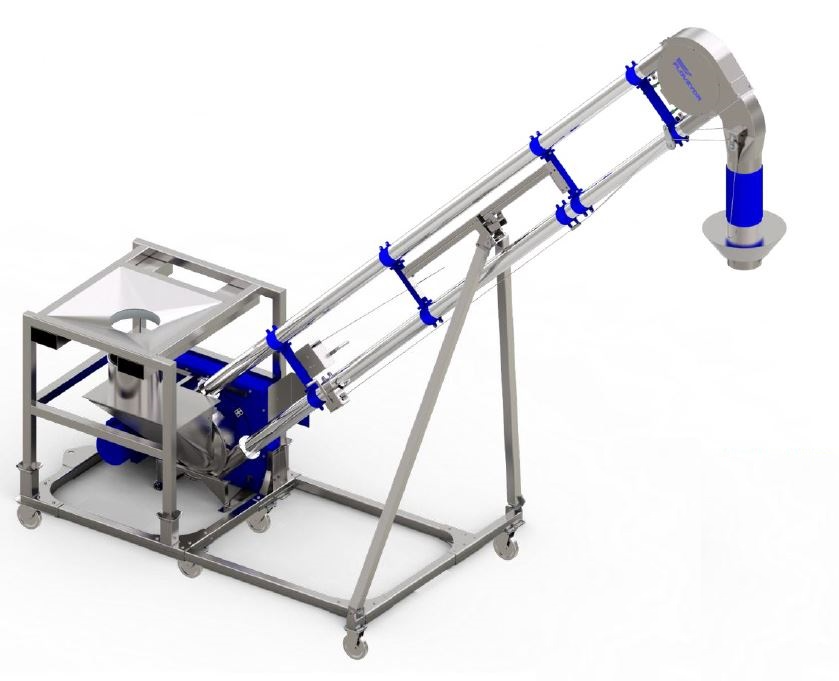

Product Conveying for Nutraceutical Ingredients

- Gough combine third party systems to ensure the best delivery system for your products

- Enclosed product conveying using a variety of different methods, including:

- Aero-mechanical using Floveyor (Gough are UK official agent) for fast, safe and product safe conveying

- Vacuum conveying for enclosed and safe transfer utilising Piab or Jenco systems.

Floveyor with Big Bag Discharger

Bucket Elevators for Nutraceutical Ingredients

- Gentle vertical transfer of powders, granules, or capsules without product damage

- Enclosed cabinet design to reduce dust emissions in nutraceutical facilities

- Safely transfer and convey product over long distances

- Modular layouts designed for supplement and functional food production lines

Gough Swinglink® Bucket Elevator

Linear Feeders and Conveyors for Powder Flow

- Deliver precise, controlled flow of vitamins, minerals, proteins, and herbal extracts

- Handle sticky or hygroscopic nutraceutical powders without clogging

- Custom discharge points to integrate with mixers, capsule fillers, or packaging lines

ATEX-Certified and Food-Grade Compliance

- Safe operation when handling combustible nutraceutical dusts (e.g. protein powders)

- Designed for traceability, hygiene, and allergen control in nutraceutical production

- Built to EFSA and UK food safety standards

Why Manufacturers Choose Gough

Gough works in partnership with nutraceutical producers to address specific production challenges — from powder flow issues to compliance audits — and design systems that scale with demand.

That partnership is backed up by:

In-house testing – trial your powders and blends before committing to investment.

Custom solutions – configured for site layouts, throughput targets, and specific ingredients.

Responsive support – long-term servicing by experienced engineers, spare parts supply from our own managed stock, and maintenance with excellent support and advise.

UK-based expertise – over eight decades supporting food and nutraceutical manufacturers nationwide.

How Will You Meet the Next Wave of Nutraceutical Demand?

The UK nutraceutical market is forecast to grow nearly 7% each year, with new formulations, stricter EFSA requirements, and clean-label expectations shaping how products are made. For manufacturers, keeping pace means more than just running faster — it means handling powders, botanicals, and active ingredients with absolute consistency and traceability.

Gough Engineering designs sieving, screening, and conveying systems proven to manage these pressures. Our solutions help nutraceutical producers maintain dosage accuracy, protect sensitive actives, and demonstrate compliance — all while scaling throughput with confidence.

📞 Speak to our team: +44 (0)1782 657770

🌐 Visit: www.goughengineering.com

Or you can go directly to the Gough Contact Form here, and begin the journey to find the right solution…