The term bucket elevator generally refers to one of two types of system: belt and bucket elevators, or pendulum bucket elevators. Despite sharing a common name, the two are quite different in terms of construction, operating principle, and application.

Construction

Belt & Bucket Elevator Systems

The basic components of a belt and bucket elevator are the belt, buckets and drums.

Buckets are fixed directly to the belt. The belt is then stretched around 2 drums, one at the head and one at the tail, much like a standard belt conveyor.

A motor drives the head drum to move the belt and buckets. This design can dredge material from the base of the machine into the bucket and elevator up to the discharge end or tipping point.

Pendulum Bucket Elevator Systems

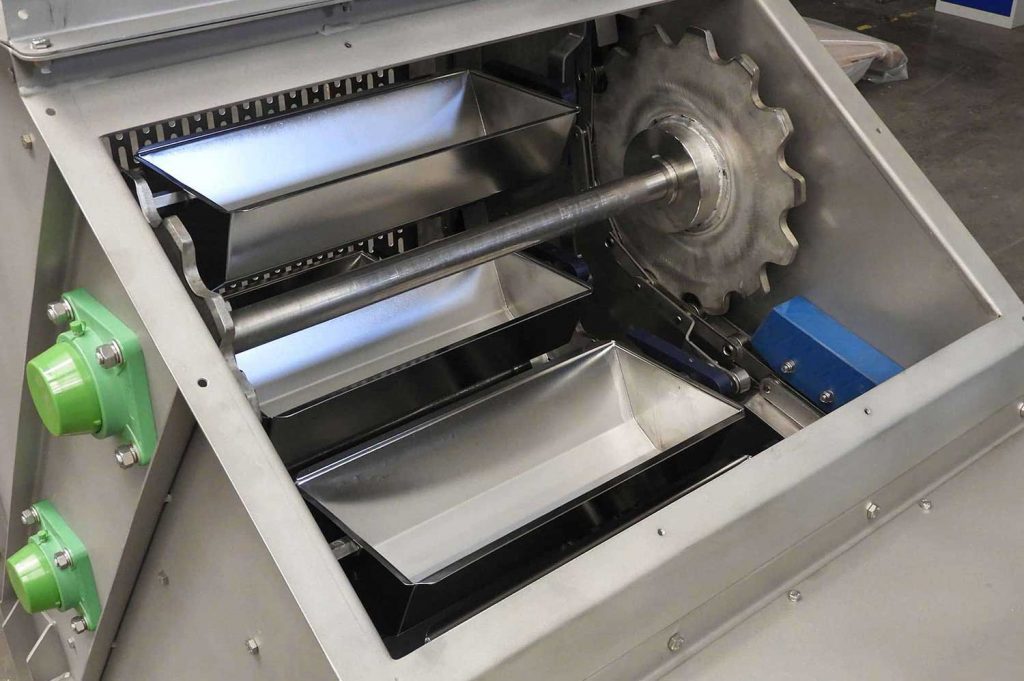

A pendulum bucket system consists of 2 chains, a series of sprockets, and the buckets.

The chains are strung around the sprockets in parallel circuits. The buckets are then suspended between the chains, and move around the circuit as the sprockets are turned.

As the buckets are not fixed to the chains, they are free to swing and remain upright throughout the circuit.

Operating Principles

Simple

The belt and bucket system is very simple.

Bulk product is poured into an inlet at the lower end of the system and falls into the buckets.

As the belt moves, the product is carried in the buckets until it reaches the head drum.

As the bucket move over the head drum; product is discharged by the centrifugal force generated as the bucket moves around the radius of the drum.

Less Simple

Pendulum bucket elevator systems are filled in a similar manner to belt and buckets, with product falling in through an inlet in a controlled manner.

At the discharge, however, pendulum buckets need to be actively tipped.

The buckets are fitted with a cam, which engages with a ramp that tips the buckets, emptying out the product.

Multiple tipping points can be designed and controlled allowing product to be delivered at different locations in the factory and associated production lines, i.e. bagging line, further processing, multi-head weigher etc.

Advantages of Bucket Elevator Systems

Fast & Cheap

The main advantages of the belt and bucket system are speed and cost.

The fixed buckets can travel at up to 20 metres per second, allowing very high rates of product throughput rates equalling 100s of cubic metres per hour.

Being a simple system, also means that they are easy to manufacture and are available at low cost.

The main drawback is the relatively narrow application range.

As product is literally thrown from the outlet, it is only suitable for durable bulk products. The systems are really only suitable for raw materials, not more fragile products.

Gentle & Flexible

Pendulum bucket systems operate more slowly, meaning they are much more gentle on the product.

This opens up more possible applications, including delicate products like handling crisps and other friable materials.

These systems are more flexible when it comes to layouts. The sprockets can be arranged to move the buckets vertically, horizontally, or at an incline.

Having to actively tip the buckets opens up the possibility of multiple discharge points, as the tipping ramps can be raised and lowered on pneumatic cylinders to tips a group of buckets, or let them pass to the next tipping position as needed.

The drawbacks are that the system isn’t able to handle the high volumes of product like the belt and bucket option. The increased complexity also means the systems are more expensive.

(Important Note) - However, the multiple tip option can also mean only one elevator system is needed, versus multiple belt and bucket elevators to complete the same function.

Find out more about our Bucket Elevator systems and how we could help you move product quickly and efficiently around your production plant here.