Heavy Duty Feeders

Vibrating feeders, like the Gough Linear Vibratory Feeder (GLVF), are often used in industrial settings to move and distribute large amounts of materials. These devices use controlled vibration to facilitate the seamless transfer of materials along production lines or into various processes and machines. The adjustable nature of vibration allows for precise customisation, enabling them to adapt seamlessly to the demands of each specific application.

Introduction

Heavy Duty?

So what does heavy duty mean?

- Large sized screen areas, which can be up to 1500mm wide, and 3,000mm long.

- Large chassis for two decks and 3 fraction if required.

- Heavy duty wire mesh screens, sometimes with integrated supporting meshes.

- Large, powerful twin out-of-balance motors.

- Rosta suspension for large and safe vibrating, permanently connected to support frame, unlike springs.

- Large, heavy duty support frames if needed.

Features

Enclosed drive units

The drive units are IP54 rated, protecting the internal components from dust and moisture.

Controls

Controllers can be provided separately or as part of control panels. They can respond to signals from processing equipment such as multi-head weighers and mixers.

Multi drive systems

Multiple drives can be fitted for large systems, all wired to the same controller.

Performance

Excellent throughput rates for your product material, with enclosure features such a top covers.

Key features of our heavy duty machines

Bespoke

The vibratory feeders supplied by Gough are designed and manufactured at our UK factory to meet the specific processing requirements of your company.

Special inlets / outlets

We understand the importance of versatility and ease of integration with your existing equipment. Therefore, we offer a variety of inlets and outlets, available in different shapes and sizes.

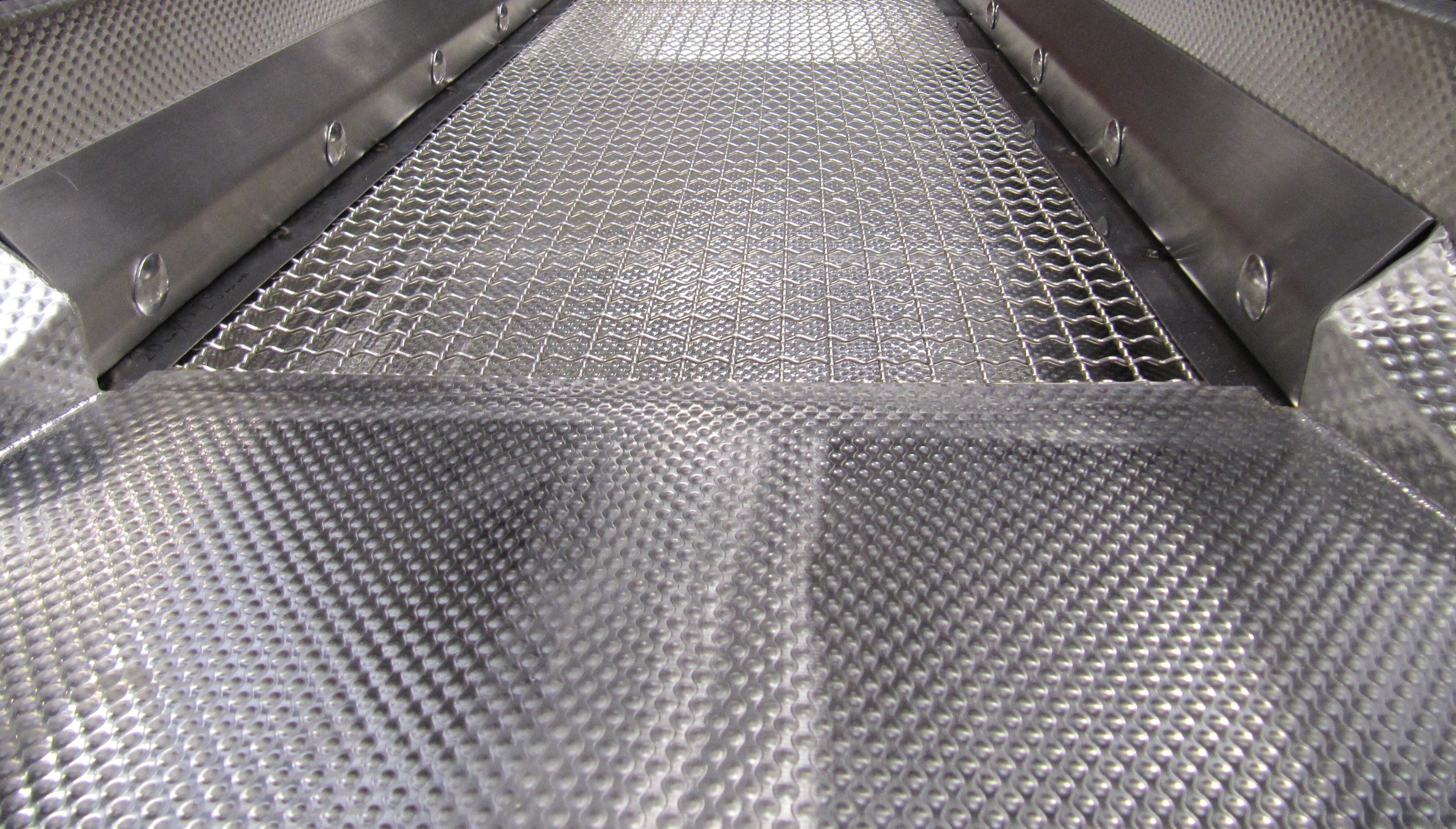

Screening plates

Incorporating screening plates into your equipment is an efficient method for the removal of fine particles from your products. Our versatile options include the use of perforated plates and screens made of woven wire mesh.

Covers

We can supply dust enclosing systems, which can be tailored to your requirements. These systems not only minimise the escape of dust but also serve as an effective barrier against cross-contamination, ensuring the integrity of products.

Contact us today

Want to find out more on our fantastic feeders and their benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com