Bucket Conveyor

Guaranteeing gentle and secure handling, bucket conveyors are a versatile and low-maintenance alternative to conventional belt conveying and elevating systems. They are a version of a bucket elevator - but just a straight run of bucket normally in the horizontal plane.

Introduction

Horizontal Bucket Conveying

Along with a standard elevator arrangement; pendulum bucket systems can be setup to provide a conveying function.

Like bucket elevators, bucket conveyors offer secure product handling around busy facilities, but are more focussed on moving product horizontally than vertically.

The bucket conveyor presents a continuous row of overlapping buckets at the inlets, and allows for single or multiple selective discharge stations so the system can be used to either split or recombine production lines.

The system is available in a range of specifications to suit the application.

Design

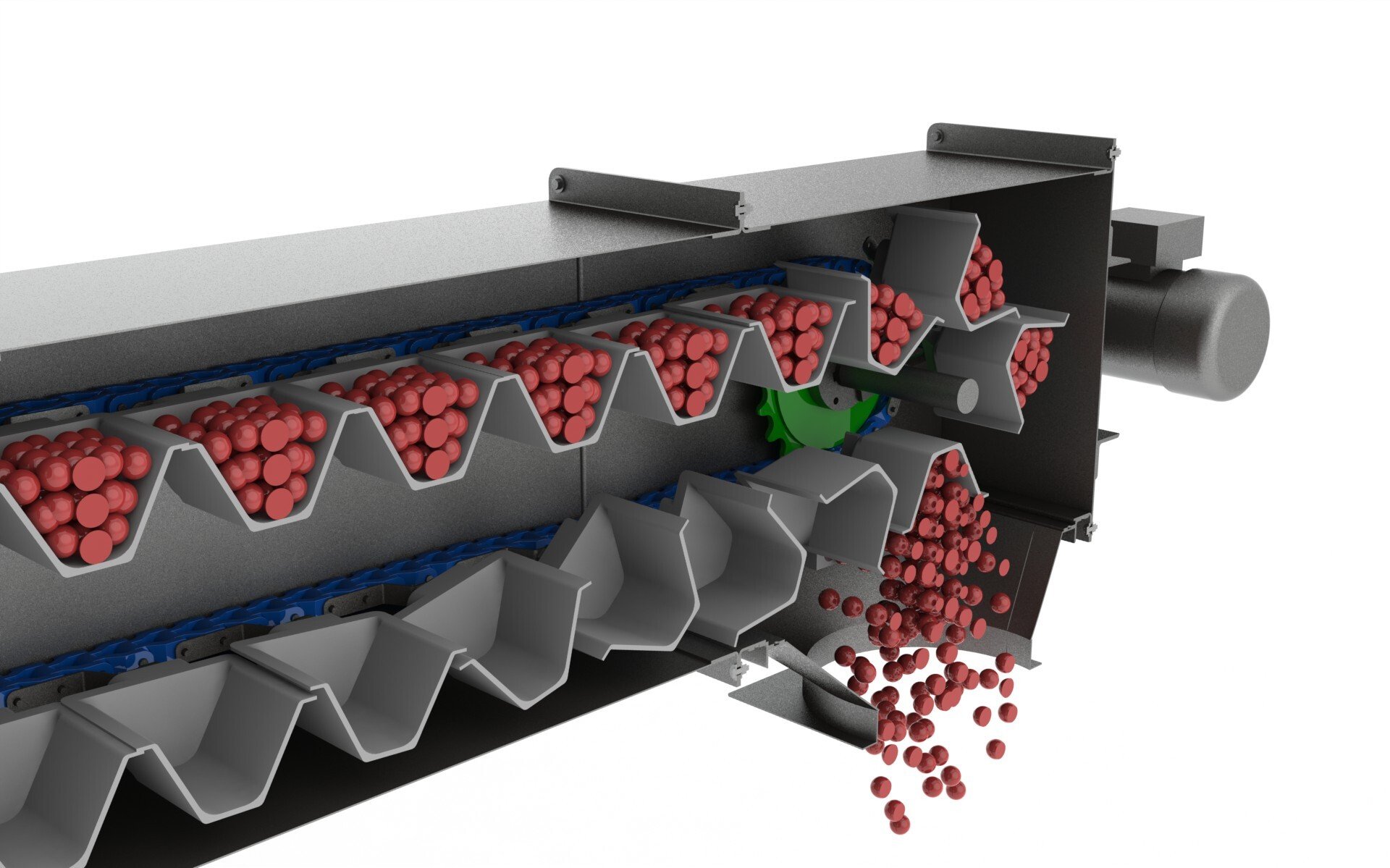

No spillage

The Swinglink design presents a continuous stream of overlapping buckets at the inlet, allowing the elevator to be fed with a constant stream of product with no spillage.

Low maintenance

Compared to conventional belt conveying systems, the horizontal bucket conveyor is very low maintenance and has no tracking or slipping issues associated with belt systems.

Lubricant free chain

The chain used in the Swinglink bucket elevator uses chain attachments fitted with rollers that run along tracks inside the casing. The rollers mean no chain lubricant is required, and buckets can travel smoothly across horizontal conveyor sections.

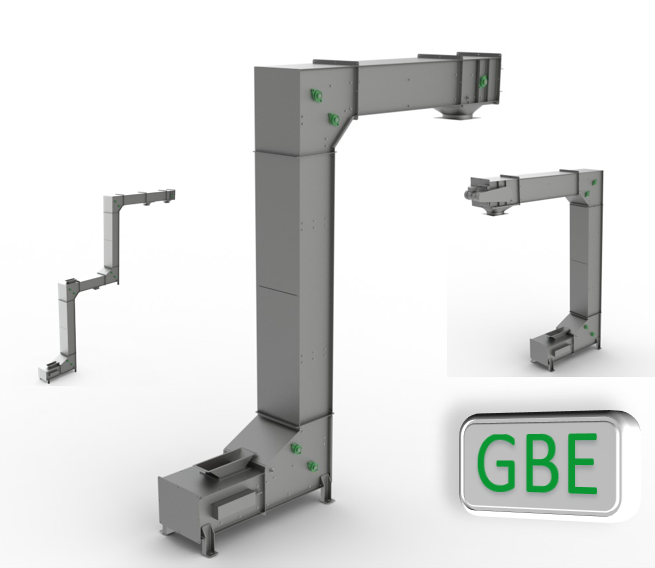

Any Configuration

With our own design team, we can design and install any configuration of bucket conveyors to bridge the gap in-between processes effectively.

Key advantages

Safe handling

Product is conveyed securely in a solid bucket, greatly reducing the risk of damaging fragile materials.

Extra long conveying

Product can be conveyed dozens of metres using one system with a single drive unit.

Multiple in & out

Systems can be set out with multiple product in-feed and discharge stations, offering the possibility of combining or separating out into multiple production lines.

Quick release

Innovative chain and track design means all conveyor buckets can be quickly removed for fast and efficient service and cleaning.

Construction

| Aspect | Screen Diameter (mm) |

|

Solid Casing |

Fully enclosed stainless or mild steel casing to prevent any foreign bodies entering the open buckets. The casing comes with quick release cover panels for service access. |

|

Tubular Frame |

Tubular framework and support structure which can be fitted with either stainless wire mesh of clear Makrolon panels for regular washdown or inspection purposes. |

|

Chain Type |

Plastic, mild and stainless steel chains are available to meet the specific application requirements. |

|

Bucket Type |

Elevator buckets are available in plastic, mild steel and stainless steel to suit application requirements. Steel buckets can also be non-stick coated. |

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Contact us today

Want to find out more on our superb conveyor solutions...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

Can a horizontal bucket conveyor work on its own without a vertical section?

How is the conveyor driven

A single energy efficient motor is designed to pull the chain and bucket through the system.