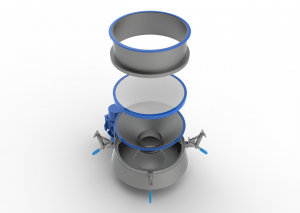

What is a Batch Sieve?

An industrial batch sieve, such as the Gough Batch Sieve or GBS, is a compact vibratory system that can transform a production process. A Batch Sieve will effectively and efficiently break up any agglomerates or clumped material at its point of input into your production process. The mesh within the sieve will be tailored to your inputs so that any debris or contaminants will be filtered out at the very beginning of manufacturing.

Does a Batch Sieve suit my production process?

Batch Sieves are designed for use in a short production run, or to process small batches. The unit can be mounted securely on a fixed support frame or attached to a mobile stand with robust castors. This makes it possible for the unit to be utilised in multiple locations within your production process.

Will a Batch Sieve improve efficiency?

A Gough Batch Sieve features a high, seamless deck rim that allows for the efficient loading of materials without the risk of spillage or wastage. This will provide a long run cost reduction within your manufacturing process. The unit is designed to use gentle vibration to move the product through, with very little need for supervision. This keeps energy consumption at a minimum, and releases labour to be utilised elsewhere in your production process. A Gough Engineering Batch Sieve will support a continuous flow, eliminating stoppages and increasing productivity.

Why choose a Gough Engineering Batch Sieve?

Commissioning your Batch Sieve from Gough Engineering gives you access to the very highest quality and decades of experience in industrial processes. You can be confident that your Batch Sieve will come with a correctly specified mesh that has been thoroughly tested in our trial lab. Our simple design offers a proven check screen process and excellent manoeuvrability to allow for a fast and efficient transfer between locations. Our Batch Sieves offer quick disassembly, allowing for cleaning and washdowns to be performed without specialist knowledge, tools or the risk of corrosion.

Should my Batch Sieve be customised to my production process?

Gough Engineering work with all our clients to ensure that the equipment they receive is the perfect solution to their production problem. Any Gough Batch Sieve will be designed with our customer in mind, and we can include:

- Magnets

- Rip & Tip stations, including shelf and hood designs

- Extraction options to reduce the spread of fine airborne powders

- Different unit height options for seamless integration

- Ultrasonics

Solution Example: A Rip & Tip Station with pivoting sieve hood with steps and enclosed base.

Solution Example: A Batch Sieve (GBS550) with integrated Floveyor for material elevation.

Call us on 01782 567770, or complete the form below or click here to send us an email about your requirements today.