Optional Enhancements & Parts

As part of our comprehensive aftersales support, Gough supply the complete range of replacement parts required to keep our vibratory sieves, screens and separators running trouble-free for years. Natural wear means that inevitably some parts will need replacing. When investing in Gough’s screening and separation equipment, you can be sure you’ll be able to get the right support at the right time.

At Gough Engineering, we understand the importance of tailoring sieves, screens and separators to meet your production requirements. That's why we, as a material handling equipment supplier, offer a range of optional extras and separator spares to enhance the performance and functionality of your equipment.

Sieve and screen re-meshing

We also offer a complete and comprehensive sieve/screen re-meshing service to all our customers.

Over time, the tension of the screen mesh may decrease. Therefore, it is crucial to ensure proper and sufficient tension to uphold optimal screening performance.

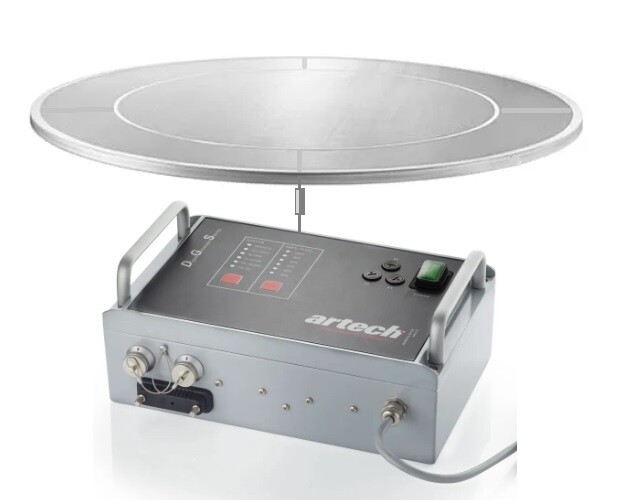

Ultrasonic options

For a more advanced and efficient solution to blockages, we offer ultrasonics as an optional extra. Using high-frequency soundwaves, ultrasonics break up any blockages on the screening mesh, maintaining optimal product flow rates with ease.

Rare earth magnets

Rare earth magnets are exceptionally strong magnets designed to capture any ferrous material and eliminate it from the final screened product. These magnets are typically installed into the outlet spout of a system, allowing for easy removal and cleaning when necessary.

These magnets are typically integrated into the outlet spout of a system, facilitating effortless removal and cleaning whenever required, ensuring uninterrupted and efficient operation.

Covers

Our entire range of screens, sieves and separators can be fitted with enclosed covers. Covers are often included in designs to prevent any dust created by the vibration, from escaping into the surrounding environment, or to minimise the chances of foreign bodies and contaminants entering the product during the screening process.

The covers can include:

- Quick release mechanisms: This streamlines the maintenance and cleaning processes. It reduces downtime and enhances overall operational efficiency.

- Dust extraction ports: Some covers come equipped with dust extraction ports, actively removing dust to further enhance cleanliness and safety in the working environment.

- Lock-off inspection ports: To facilitate monitoring of the screening process without the need to remove the covers entirely, lock-off inspection ports are integrated into some cover designs. This allows for efficient inspection and maintenance while maintaining containment.

Ball Tray

Screening meshes can occasionally become obstructed or blinded, especially when dealing with fine powders and small aperture meshes. Such blockages can significantly restrict product flow, leading to decreased throughput and processing efficiency of the system.

To address this issue effectively, a straightforward solution involves installing a de-blinding ball tray below the screening mesh. As the machine vibrates, the rubber balls gently bounce against the screening mesh, knocking any blockages loose and maintaining consistent product flow rates.

Tundish and distribution cones

Tundish and distribution cones play a crucial role in directing the flow of product onto the central area of the screening surface. This strategic placement ensures optimal use of the screening mesh.

As the screens, sieves, and separators apply vibratory action, the product moves across the screening surface in an outward spiral pattern. Therefore, precise placement of the product onto the central area is essential for maximising the effectiveness of the screening process.

When multiple decks are in use simultaneously, distribution cones fitted below the screening decks guarantee the product lands accurately on the central area of each deck. This ensures uniform and efficient screening across all decks.

Flexible connectors

Flexible connectors are available to accommodate inlet and outlet spigots, effectively preventing product spillage and the escape of dust into the surrounding environment. These connectors provide a secure seal while allowing for flexibility in system configuration.

Stands and castors

We offer the option to customise support stands and framework for easy integration of our screens and sieves into your production process. Screens and sieves can also be fitted with castors so the units can be moved in and out of place as needed.

Earthing wires

In systems handling powders, there's a risk of static charge build-up. To prevent potential hazards like static shocks, equipment damage and explosions, we offer earthing wires. These wires effectively dissipate static charge build-up, ensuring a safe and secure operational environment.

Contact us today

Want to find out more on our options and solutions...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com