Protein Extraction

At Gough Engineering, we specialise in delivering advanced material handling solutions to meet the growing demand for efficient and reliable protein extraction processes. Whether handling fine powders or separating plant-based and animal-derived proteins, our equipment is designed to maintain product quality while maximising operational efficiency. Our bulk material handling systems provide seamless integration across a range of industries, from food processing industries and food production and beverage to nutrition and pharmaceuticals.

Custom designed ...

Our expertise in custom-engineered equipment allows us to create tailored solutions for every stage of protein extraction. From conveying powders to sieving and separating materials, we provide high quality, high-performance equipment designed to ensure precision, reduce downtime, and minimise contamination risks.

Our solutions include everything from bucket elevators, vibrating feeders, aero-mechanical conveying, vacuum transfer systems, to circular vibrating sieves or separators to linear machines that are ideal for handling protein powders.

Key Features

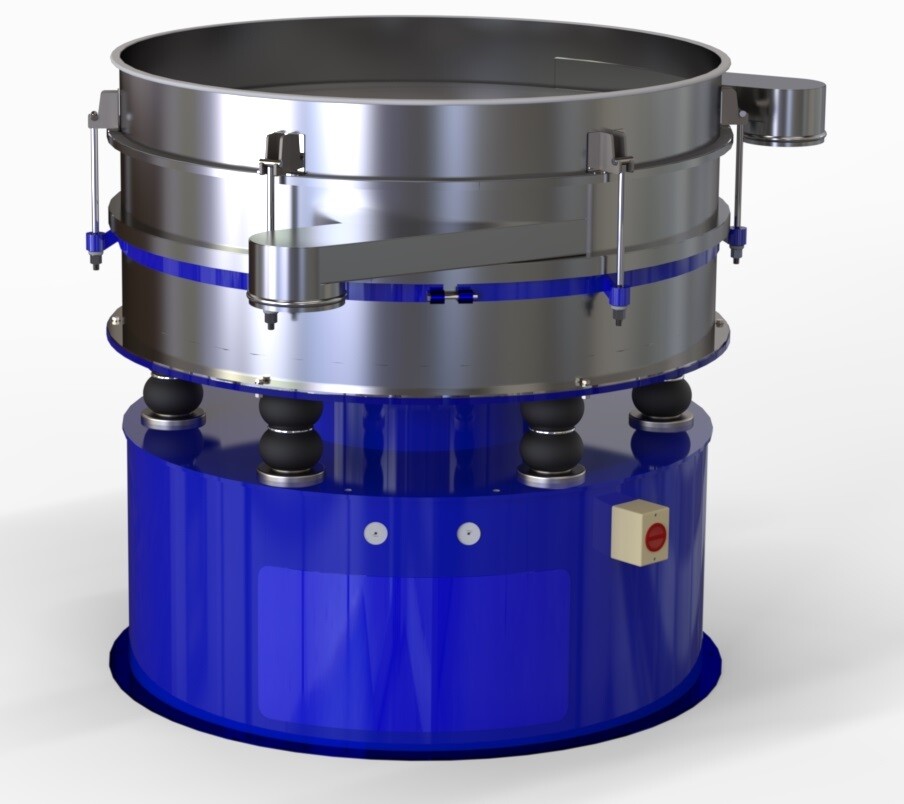

Vibrecon Machines

Delivers precise separation of protein powders at high capacity and high speeds, ensuring product consistency across large volumes. This vibrating screen provides efficient separation into three fractions (oversize, good and fines) while maintaining the quality of sensitive materials.

Aero-mechanical

Designed to handle protein powders with minimal dust generation with full enclosure, ensuring safe and efficient transfer.

Batch Sieves

Maintain product purity by preventing contamination during screening processes. Our industrial sieves are essential for handling both plant-based and animal-derived protein powders, ensuring optimal separation and safety, including specific applications like high abrasion materials.

Metals?

If required, Gough also combine metal detection systems into final screening of ferrous metals within products to improve final quality assurances.

Total Support

At Gough Engineering, we are committed to delivering a seamless installation process, from initial consultation to final commissioning. Our experienced engineers will integrate our vibratory feeders, bucket conveyors, and belt conveyor systems into your production line with minimal disruption. We also provide ongoing support to ensure that your systems, including our vibrating sieves and screen vibration technology, continue to perform at their best.

Supporting sustainable production

As the demand for alternative proteins continues to rise, our systems are developed to support manufacturers in food processing industries, food and beverage manufacturing, nutrition, and pharmaceutical industries. Our screening machines and food conveyor belts ensure that your production line remains efficient while meeting stringent regulatory standards for product quality and safety.

The food processing process is streamlined by our tailored solutions, designed to ensure efficiency and reliability at every stage of production. From raw material handling to final packaging, our systems are built to support the processing and production of protein powders, offering flexibility and scalability as demand increases.

Reality Case

When a major protein supply company in the UK needed to improve its protein production line to accommodate in-line check screening, metal detection before requiring a new bagging line, they turned to Gough Engineering.

Our team installed the Gough Batch Sieve (GBS), a vibrating screen that enabled fast, efficient check screening of contaminates before an in-line metal detection system (with auto-removal of ferrous metals) and a Robbe bagging unit. This solution allowed the customer to meet high quality standards for taste and quality while increasing production throughput.

Contact us today

Want to find out more on our wonderful material handling solutions and their benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email

contact@goughengineering.com