Floveyor (aero-mechanical conveyors

Gough Engineering is the UK’s Floveyor partner for aero-mechanical conveying solutions. Floveyor first invented the aero-mechanical conveyor in 1958. There have been many lesser imitations sold over the years but none have been able to match the modern aero-mechanical technology offered by Floveyor.

Introduction

Robust & Fast Transfer

As the UK’s Floveyor partner, Gough Engineering provides completely new systems, replacement of rope assemblies, full parts and maintenance services and support. Our aim is to simplify your materials handling with a clean and safe conveying solution. For an uncomplicated, versatile and economical materials conveying solution, choose a Floveyor.

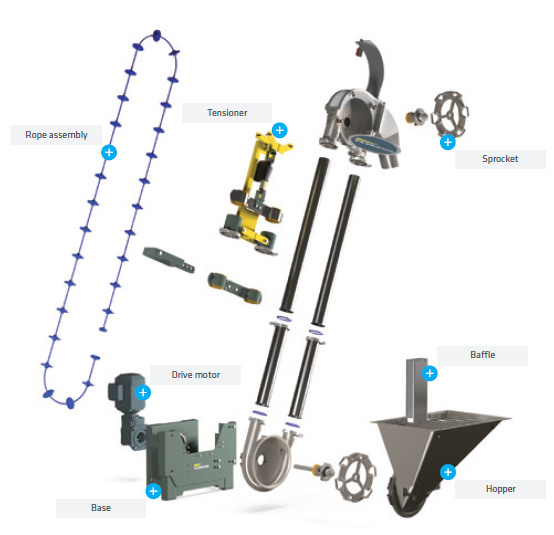

Floveyor equipment is used to convey granules, dry powders, flakes or pellets. An example of efficient engineering, the aero-mechanical conveyors use a compact motor to power an internally circulating rope assembly at high speed. The circulating rope generates pockets of fast-moving air that suspends and conveys the product to the upper housing, where it is discharged via centrifugal force to the desired collection point.

A unique materials handling system, Floveyor fluidising technology is suitable for a number of industry applications.

Applications

Conveying

Pioneers in powder handling with the invention of the aero-mechanical conveying solution.

Bag Unloading

With Gough Rip&Tip stations, Floveyors can unload and convey material for the next process very effectively.

Container Unloading

Floveyor can enhance the efficiency of bulk material supply chains with container unloading systems catering to a wide array of industrial needs, from food processing to chemicals.

Truck Loading

Designed to enhance the efficiency and safety of loading operations, Gough can integrate with checks screens and final metal auto-rejection system for clean product delivery.

Key advantages of our sieving machine

Footprint

Small equipment footprint capable of high throughputs: the system can convey over 100m3/hr of product, using only a few square meters of factory space.

Gentle handling

The gentle transport of materials: suspending product in pockets of air provide surprisingly gentle handling for such a high speed system.

Hygienic options

Minimal residue and easy-to-clean systems: Floveyor aero-mechanical conveyors operate in food processing applications where hygiene is of paramount importance.

Super ergonomics

The Gough Batch Sieve (GBS) is designed and tailored to your operations, keeping health & Safety a priority.

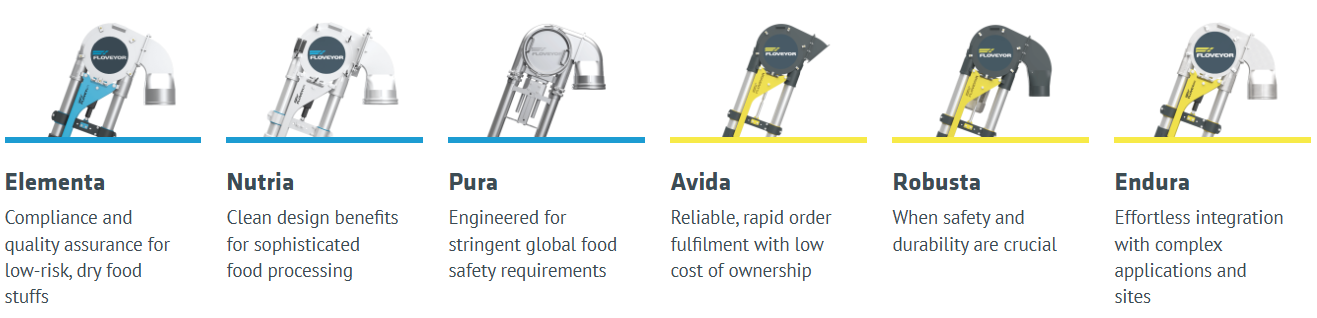

Floveyor Model Range

| Model |

Tube Size |

Particle Size |

Throughput |

|

F3 |

3 inch (76.2mm) |

Min <=6mm |

15 tph |

|

F4 |

4 inch (101.6mm) |

Min <=9mm |

30 tph |

|

F5 |

5 inch (127mm) |

Min <=12mm |

54 tph |

Exploded View of Floveyor

Floveyor & Gough for bag Rip & Tip operations with integrated quality checking on a mobile support frame .

Materials Handled by Floveyor

Floveyor Options

Direct linear

Flexible configurations from vertical to horizontal, adapting to any inclination.

Horizontal

Ideal for high volume conveying within a compact horizontal footprint.

Bi-directional

Perfect for efficient high volume conveying with dual outlet options.

Mobile

The ultimate in versatility, efficiency, and lean powder conveying solutions.

Corner unit

Available in vertical to horizontal or horizontal to vertical configurations for seamless direction changes.

Dual corner unit

Configurable as vertical-horizontal-vertical or any dual corner arrangement for complex layouts.

Reality Cases & Articles

From the history archives, we can refer to many different success stories of how our machines have helped industry.

For each of the core products, we provide a bit more insight on our designs and how the solution helped a company face production issues of quality, production throughputs, reliability and product flexibility.

Improving supply chain efficiency with bulk material handling

In a recent study by Gartner, supply chain organisations identified their primary focus areas as driving commercial growth through...

Contact us today

Want to find out more on the fantastic Floveyor solution and all its benefits...

Call our sales team to discuss your requirements on:

+44 (0)1782 567770

or via email contact@goughengineering.com

Q & A

Here are a few questions and answers and we are always available to call and discuss you application specifics.

What electrical drive does a Floveyor use?

Can Floveyor machines have ATEX certification?

Yes, Floveyor carry out ATEX certification depending on your application's specific ATEX requirements and zone ratings.

Does Floveyor need to be fixed unit or can it be mobile?

What speed do the ropes move at?

Typcaclly, the rope moves a speed of 4 m/s.

Does the discs drag and damage the product?

No, the discs and their speed create a vacuum behind the leading disc, protecting the product material from degradation for any free-flowing bulk material. It is pulled therefore, not dragged or pushed through the pipes.